−

2

−

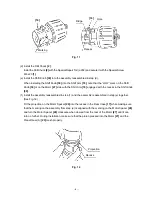

Fig. 4

(4) Disassembly of the gear unit.

Remove the Shift Arm [18] from the Rear Case [17], then remove the four Screw Sets D3 x 12 [4]

connecting the Front Case [11] and the Rear Case [17]. Remove the Washer (A) [16], the Planet Gear

(C) Set [15], Carrier [14], Ring Gear [13] and Steel Ball [12] from the Front Case [11] in order. Take

care not to lose the six Steel Balls [12] in this operation.

(5) Disassembly of the clutch unit.

Remove the two Screw Sets D3 x 12 [4], then remove the Plate [5], Cap [6], Clutch Plate [7], Spring

[8], Spring Holder [9] and Thrust Plate [10].

(Note) Do not remove the Front Case [11].

(6) Disassembly of the power supply unit.

(Note) Do not disconnect the three FET internal wires soldered to the DC-Speed Control Switch [36].

Disassembly of the Motor [27], DC-Speed Control Switch [36], Motor Spacer [26] and Fin [43] removed

in step (3) can be carried out in the following procedure.

Disconnect the Internal Wires [35] and [38] of the Motor [27] with a soldering iron.

With one Bind Screw M3 x 7 [42] removed, the FET (Field Effect Transistor) of DC-Speed Control

Switch [36] and the Fin [43] can be taken apart.

Remove the two Machine Screws M4 x 6 [30] and take the Motor [27] and the Motor Spacer [26] apart.

When removing the Internal Wires [35] and [38] of the Motor [27] from the DC-Speed Control Switch

[36], be sure to remove the two Machine Screws M3 x 5 [34] securing the flag-shaped terminal. (See

Fig.5.)

Rear Case [17]

Slide Ring Gear [19]

Drill Chuck [2]

Special Repair Tool (J-292)

Shift Arm [18]

Hexagonal bar wrench

Vise

Front Case [11]

Cap [6]

M6 x 23 [1]

Special Screw