--- 28 ---

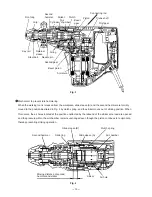

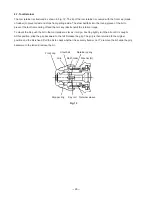

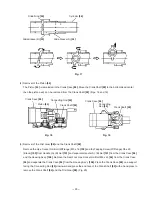

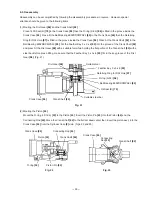

(5) Lubrication

Apply Hitachi Motor Grease No. 29 to the following places:

Apply 30 g (1 oz) to the gears in the Gear Cover

[100]

and the Crank Case

[94]

, and coat grease on the

Needle Bearing (M661)

[99]

(motor ass'y), Steel Ball D7.0

[17]

, pinion of armature ass'y.

Apply special grease (grease for electric impact drill) to the following places:

Apply 30 g (1 oz) to the Connecting Rod

[45]

in the crank case.

Apply 10 g (0.3 oz) to the inside of the Cylinder Case

[9]

.

Coat grease on the inside diameter of the Connecting Rod

[45]

of the piston ass'y, O-ring (C) of the Second

Hammer

[23]

, O-ring (I.D 19.2)

[32]

, sliding portion of the Second Hammer

[23]

, Damper

[25]

, Damper (C)

[29]

, O-ring

[62]

, inside and outside diameters of the Bevel Gear

[41]

, inside diameter of the Clutch

[40]

,

inside diameter of Slide Sleeve (A)

[34]

, inside diameter of Slide Sleeve (B)

[33]

, inside lip portion of Oil Seal

(B)

[75]

and inside lip portion of the Oil Seal

[11]

.

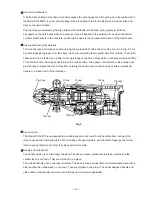

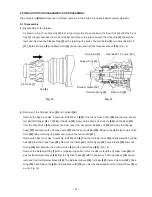

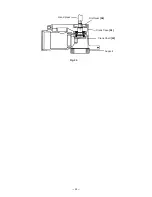

(6) Oil seal and others

Be careful not to scratch the following parts:

Oil Seal

[11]

and O-ring

[10]

of the Cylinder Case

[9]

Oil Seal (B)

[75]

and O-ring (S-32)

[96]

of the Crank Case

[94]

O-ring (C) of the Second Hammer

[23]

O-ring (I.D 19.2)

[32]

of the Piston

[44]

and the Striker

[31]

O-ring

[62]

of the Lever Shaft

[61]

O-ring (S-48)

[91]

of the Crank Case Cover

[90]

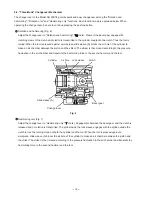

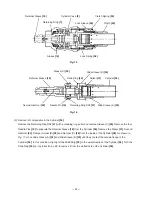

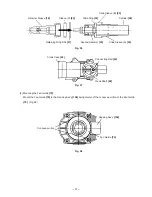

9-3. Screw Locking Agent TB1401

Apply screw locking agent TB1401 to all hex. socket head bolts M4, M5 and M6.

Note: Be sure to apply screw locking agent ThreeBond TB1401 to the threads during reassembly, as the

bolts loosened with vibration may cause damage to the tool body.