--- 13 ---

8. REFERENCE INFORMATION

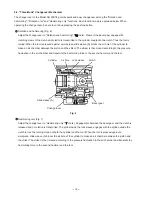

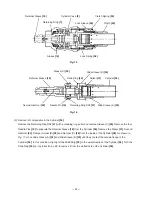

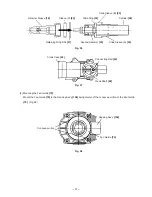

8-1. Grease Replacement

The striking portion and the speed reduction portion of the Model DH 30PC2 respectively use different types of

grease. It is not necessary to replenish the grease unless the tool is disassembled for repair or there is grease

leakage due to a damaged seal. The striking portion uses special grease. To change the grease in the striking

portion (inside the crank case and cylinder case), carefully wipe the old grease off the parts, and re-lube with 30 g

(1 oz) into the crank case (connecting rod side) and 10 g (0.3 oz) into the cylinder case. Take care not to overfill

the grease as an excessive amount of grease can cause hammer failure.

The speed reduction portion (inside the gear cover) uses Hitachi Motor Grease No. 29. The proper supply volume

is 30 g (1 oz). Never use the striking portion special grease in the speed reduction portion. Special grease would

leak into the motor portion and cause subsequent trouble.

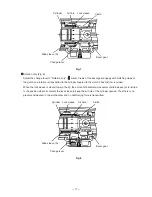

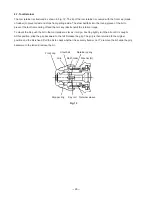

8-2. O-ring Replacement

The O-rings (mounted on the striker and piston) are extremely important to ensure adequate sealing of the air

pressure. Although the O-rings are made of special rubber to give them a long service life, they do nonetheless

become worn, and should be replaced by new ones periodically depending on frequency of use of the tool. With

average use, it is recommended that the O-rings be replaced at least every six months to ensure maximum

effectiveness.

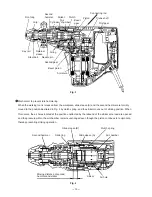

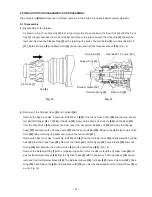

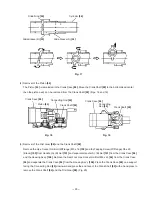

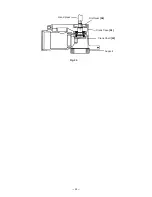

8-3. Structure of the Model DH 30PC2 Rotary Hammer

Torque transmission

Armature revolution is transmitted to the second gear to rotate the bevel gear via the slip mechanism between

the second gear and bevel pinion axes. Rotation of the bevel gear is then transmitted to the cylinder keyed

thereto through the clutch. Cylinder rotation is conveyed to the retainer sleeve coupled together by means of

four needle pins and, then to the drill bit inserted into the retainer sleeve by way of two key rails and two steel

balls which couple them together.

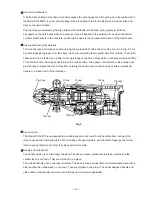

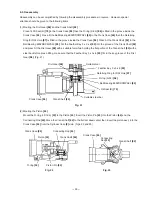

Striking operation

The rotation of the armature is transferred to the crank shaft and connecting rod, which in turn cause the

piston to reciprocate inside the cylinder. As the piston reciprocates, the changing air pressure inside the air

chamber between the piston and the striker causes the striker to continuously strike against the end of the

second hammer. At the same time, the air-cushion effect within the air chamber absorbs the impact of the

striker. Should the air escape from the air chamber, the air-cushion effect would cease, and the impact energy

would not be absorbed. Accordingly, the O-rings mounted on the striker and the piston play an extremely

important role in sealing the air within the air chamber.