--- 26 ---

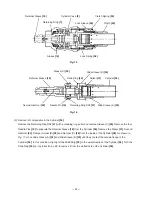

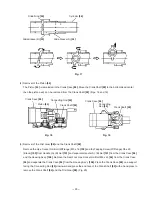

(3) Mounting components in the Cylinder

[36]

Fit Slide Sleeve (A)

[34]

and Slide Sleeve (B)

[33]

on the outer circumfenrence of the Cylinder

[36]

and move

Slide Sleeve (A)

[34]

and Slide Sleeve (B)

[33]

until they contact the outside flange of the Cylinder

[36]

. At this

time, align the slotted hole of the Cylinder

[36]

with the groove of Slide Sleeve (B)

[33]

. (Fig. 24)

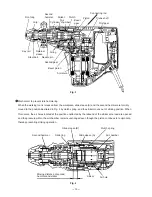

Fig. 25

Groove

Slide Sleeve (A)

[34]

Cylinder

[36]

Slide Sleeve (B)

[33]

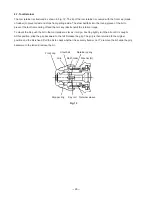

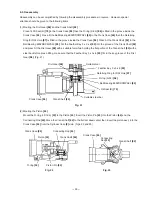

Mount the Second Hammer

[23]

, Damper Washer

[24]

, Damper

[25]

, Damper Holder

[26]

, Damper Holder (B)

[28]

and Damper (C)

[29]

to the inside of the Cylinder

[36]

. Mount the Damper Washer

[24]

so that the R

surface of the inside diameter is aligned with the R surface of the Second Hammer

[23]

. Mount the Damper

Holder

[26]

so that its flat surface without difference is faced to the Damper

[25]

. Fit the Retaining Ring D38

[21]

and Sleeve (C)

[20]

on the outer circumference of the Cylinder

[36]

then insert the Cylinder

[36]

into the

Retainer Sleeve

[18]

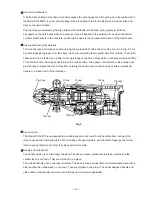

. (Fig. 26)

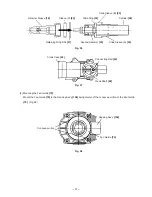

Connect the Cylinder

[36]

and the Retainer Sleeve

[18]

with the four Needle Pins

[19]

. Fit Sleeve (C)

[20]

on

the outer circumference of the Retainer Sleeve

[18]

and fix it with the Retaining Ring D38

[21]

.

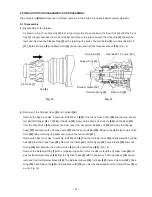

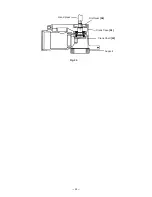

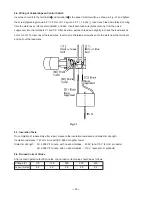

To connect the Cylinder Case

[9]

with the Crank Case

[94]

easily, move the Crank Shaft

[92]

and move the

Piston

[44]

to the top dead center, then insert the Piston

[44]

in the Cylinder

[36]

. (Fig. 27)

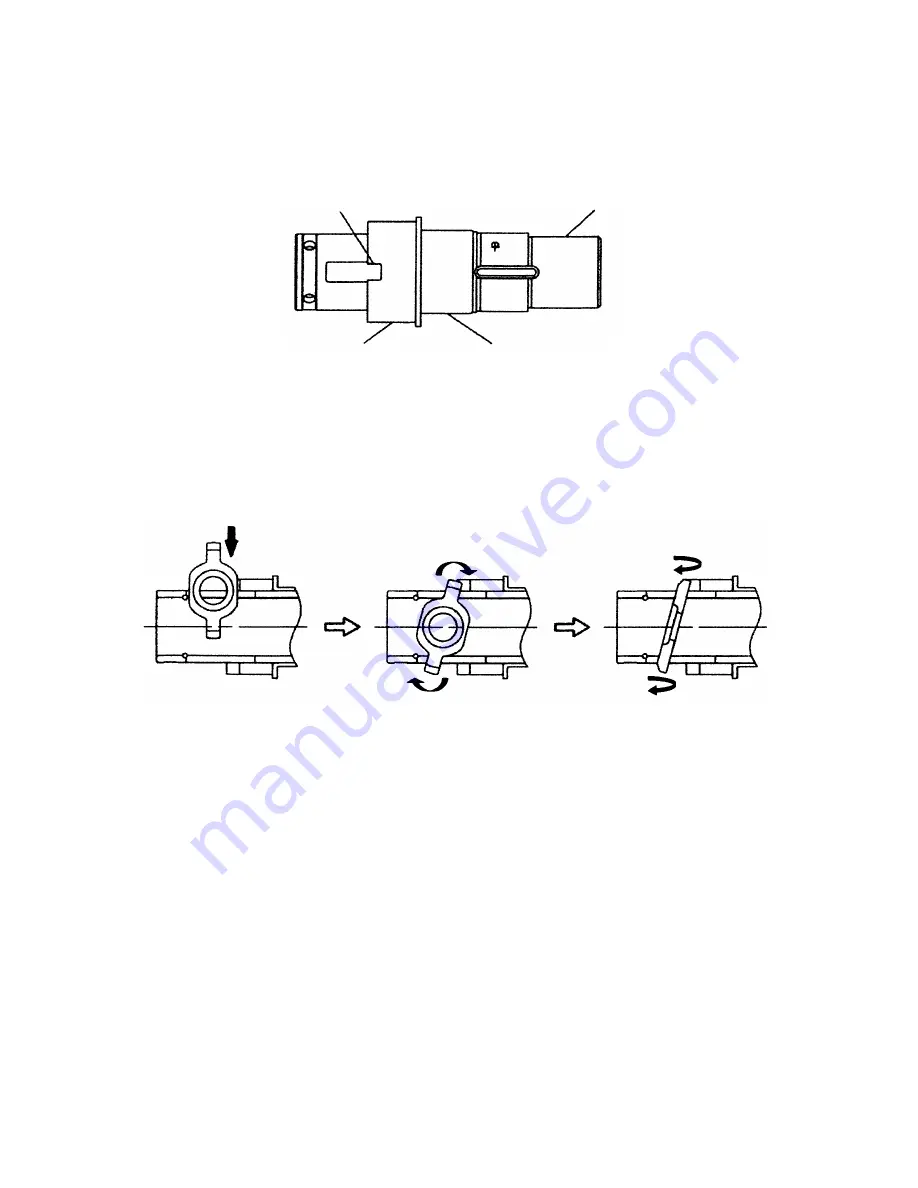

Fig. 24

Put the Slide Ring

[30]

in the Cylinder

[36]

through the slotted hole. Tilt the Slide Ring

[30]

slightly to the axial

direction of the Cylinder

[36]

and turn the Slide Ring

[30]

on its protrusion by 90

û

. (Fig. 25) Be careful not to

deviate the protrusion of the Slide Ring

[30]

from the groove of Slide Sleeve (B)

[33]

during mounting.