To replace the component, reverse the removal procedure.

Removing and replacing the SFF optical drive

Prerequisites

Before you perform this procedure, make sure that you have a T-10 Torx screwdriver available.

Procedure

1.

2.

Remove all power:

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

3.

Do one of the following:

•

Extend the server from the rack.

•

Remove the server from the rack.

4.

5.

6.

Disconnect all cables from the SFF universal media bay.

7.

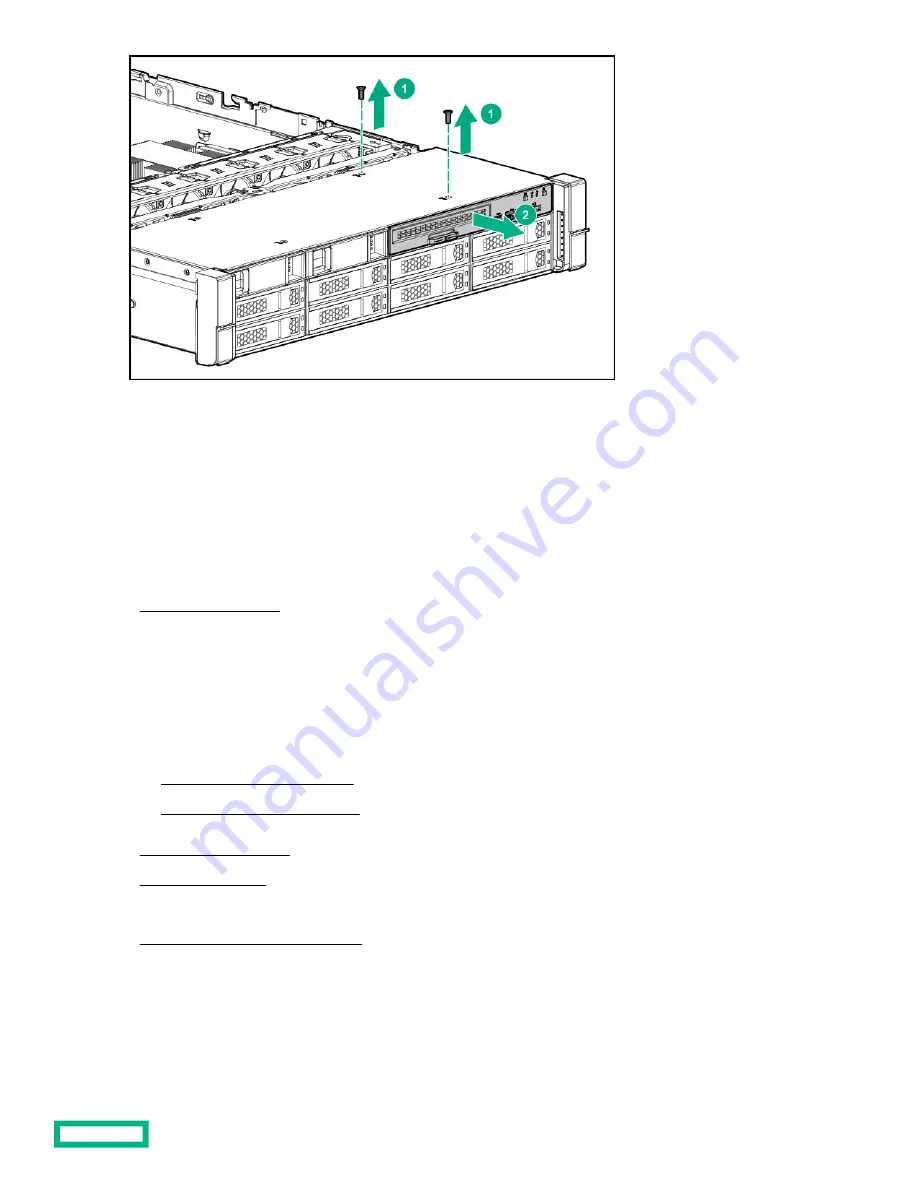

Remove the SFF universal media bay.

8.

Remove the optical drive.

Removal and replacement procedures

64