7

General oPeraTinG inforMaTion

user disPlays/seTTinGs

General Operation

When the system is operating, one of

several displays may be shown. Pressing

NEXT will alternate between the displays.

One of the displays is the current time of

day. The second display is the follow-

ing: days to a regen/gallons remaining.

Days To A Regen is the number of days

left before the system goes through a

regeneration cycle. Capacity remain-

ing is the number of gallons that will be

treated before the system goes through

a regeneration cycle. The third display

is current flow in gal/min. The user can

scroll between the displays as desired

by pushing NEXT or display will scroll

automatically.

When water is being treated (i.e. water

is flowing through the system) the word

"GPM" flashes on left side of display when

other than flow rate is displayed.

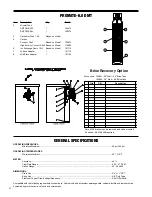

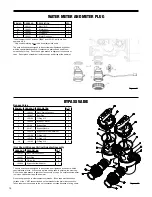

Figure 7

DAyS TO A REgEN

6

CAPACITy REMAININg

650

REgEN TODAy

gAL

NORMAL OPERATION SCREENS

PM

6:35

TIME OF DAy

gPM

6.8

FLOW RATE

USER DISPLAy 1

Typical user

display. Shows

capacity or days

remaining before a

regeneration.

USER DISPLAy 2

Displays current time.

USER DISPLAy 3

Displays present flow

rate.

REgEN TODAy

flashes in upper left

corner of display

between rotating dis-

play when REGEN

button pushed once.

gPM

Flashes when the

turbine is rotating.

User screens will continuously scroll, switching

views every 3 seconds. If the screens are manu-

ally scrolled, this screen will remain constant for

5 minutes then continue to scroll. The conditional

screens will take precedence over the scrolling

and the conditional conditions will apply.

To manually reduce capacity, press down button

while capacity remaining or days to a regen is

displayed.

DEALER NAME

DEALER PHONE NUMBER

gPM

May display if service is required.

Sometimes there is a need to regenerate the system sooner than when the system calls

for it, usually referred to as manual regeneration. There may be a period of heavy water

usage because of guests or a heavy laundry day.

To initiate a manual regeneration at the preset delayed regeneration time, press and

release “REGEN”. The words “REGEN TODAY” will flash in left corner of display as

it scrolls through displays to indicate that the system will regenerate at the preset

delayed regeneration time. If you pressed the “REgEN” button in error, pressing the

button again will cancel the request.

To initiate a manual regeneration immediately, press and hold the “REGEN” button for five seconds. The system will begin to regen-

erate immediately. The request cannot be cancelled. You must cycle all the way through the cycles to make it stop. PLEASE NOTE:

This will reset the meter.

Note: If the salt tank does not contain salt, fill with salt and wait at least two hours before regenerating. If two regenerations

are desired within 24 hour period, press /release REGEN button. REGEN TODAY will flash on screen. Press and hold REGEN

button until valve initiates regeneration.

"REgEN TODAy"

320

CAPACITy REMAININg

gAL

Manual reGeneraTion

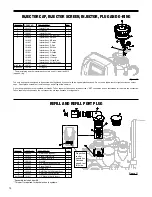

1. Salt Usage: See your water conditioning professional for a rec-

ommendation on the best type of salt for your application. See

page 3 - Maintaining Salt Level.

2. Brine Tank Cleaning:

a. Remove brine tank cover.

b. Scoop out as much old salt as possible.

c. Disconnect brine tubing from safety brine valve at brine well.

d. Remove safety brine valve from brine well.

e. Place one hand in brine well to hold overflow nut and

remove 2-piece overflow.

f. Remove brine well and optional grid plate, if used, from

brine tank.

g. Remove any remaining salt and/or impurities from brine

tank.

h. Using clean water and a brush or rag, wipe and rinse inside

of brine tank. Wipe and rinse the grid plate and brine well.

i. Reassemble brine tank reversing steps c - f. Note: If grid

plate is used and it is damaged or cracked, replace with

new one.

j. Put brine tank in place making sure there is no debris or

foreign material beneath it.

k. Reconnect brine tubing to safety brine valve.

l. Manually add 6 inches of water to the brine tank (or to

approximately 1” above the grid plate, if used).

m. Add new salt. Important: Do not add the old salt which was

removed earlier unless it is clean and not mushy. We

recommend using new salt.

n. Follow the disinfection instructions found at top of page 8.

o. Put on brine tank cover.

MainTenanCe