13

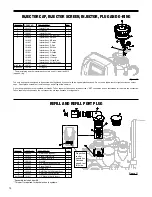

injeCTor CaP, injeCTor sCreen, injeCTor, PluG and o-rinG

refill and refill PorT PluG

1

101375

Injector Cap

1

2

102159

O-ring 135

1

3

102457

Injector Screen

1

4

102319

Injector Assy. Z Plug-Filter

1

5

101825

Injector Assy. A Black

1

101826

Injector Assy. B Brown

101827

Injector Assy. C Violet

101828

Injector Assy. D Red

101829

Injector Assy. E White

101830

Injector Assy. F Blue

101831

Injector Assy. G Yellow

101832

Injector Assy. H Green

101833

Injector Assy. I Orange

101834

Injector Assy. J Light Blue

101835

Injector Assy. K Light Green

Not Shown 106767

O-ring 011

*

Not Shown 106768

O-ring 013

*

QTy.

ITEM NO. ORDER NO.

DESCRIPTION

* The injector plug and the injector each contain one 011 (lower) and 013

(upper) o-ring.

The nuts and caps are designed to be unscrewed or tightened by hand or with the special plastic wrench. Do not use a pipe wrench to tighten or loosen nuts or

caps. Do not place screwdriver in slots on caps and/or tap with a hammer.

Do not use pipe dope or other sealants on threads. Teflon tape must be used on threads of the 1” NPT connection and on the threads for the drain line connection.

Teflon tape is not necessary on the nut connection nor caps because of o-rings seals.

Figure 10

Figure 11

*Assembly includes item #8.

**This part is required for backwash only systems.

1

102322

Refill Port Plug Assy.**

1

2

101414

Elbow Locking Clip

1

3

101868

Polytube Insert 3/8

1

4

102130

Nut 3/8

1

5-8

103589

3/8” Refill Elbow Assembly

1

5

101620

Elbow Cap 3/8

1

6

102153

O-ring 019

1

7

102418

Refill Flow Cntrl Retainer Assy.

1

8

102421

Refill Flow Control Button

1

Not Shown 101617

1/2” Elbow w/Nut & Insert

1

QTy.

ITEM NO. ORDER NO.

DESCRIPTION

Proper flow

control

orientation

Rounded

edge & text

this side