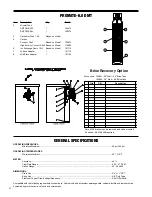

14

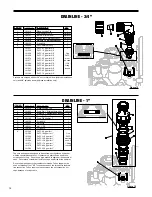

drain line - 3/4”

drain line - 1”

1

101414

Elbow Locking Clip

1

2

101635

Drain Ftg, 1” Straight Assy-Vent

optional

2 101636 Drain Ftg, 1" Straight Assy-No Vent 1

3*

101244

Drain Ftg Body, 1”

1

4*

101160

Drain Ftg Adapter, 1”

1

5*

102153

O-ring 019

1

6*

102437

Split Ring

1

7*

102141

Nut, 1” QC

1

8*

102165

O-ring 215

1

9

101599

DLFC 9.0 gpm for 1”

101562

DLFC10.0 gpm for 1”

One

101564

DLFC 11.0 gpm for 1”

DLFC

101567

DLFC 13.0 gpm for 1”

must be

101568

DLFC 15.0 gpm for 1”

used if

101571

DLFC 17.0 gpm for 1”

1” fitting

101578

DLFC 20.0 gpm for 1”

is used

101580

DLFC 25.0 gpm for 1”

QTy.

ITEM NO. ORDER NO.

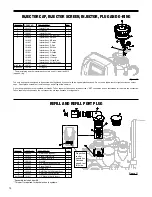

The nuts and caps are designed to be unscrewed or tightened by hand or

with the special plastic wrench. If necessary a pliers can be used to un-

screw the nut or cap. Do not use a pipe wrench to tighten or loosen nuts or

caps. Do not place screwdriver in slots on caps and/or tap with a hammer.

Do not use pipe dope or other sealants on threads. Teflon tape must be

used on threads of the 1” NPT connection and on the threads for the drain

line connection. Teflon tape is not necessary on the nut connection nor

caps because of o-rings seals.

Figure 12

Figure 13

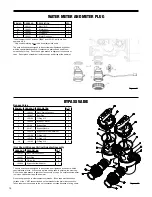

Systems are shipped without 3/4” nut for drain elbow (polytube installation

only) and 5/8” polytube insert (polytube installation only).

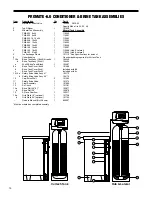

1

101414

Elbow Locking Clip

1

2

101871

Polytube Insert, 5/8”

Optional

3

102131

Nut 3/4” Drain Elbow

Optional

4-5

101618

Drain Elb 3/4" Male Assy-Vent

Optional

4-5 101619

Drain Elb 3/4” Male Assy-No Vent

1

5

102153

O-ring 019

1

6

102406

DLFC Retainer Assy.

1

7

101551

DLFC 0.7 gpm for 3/4”

1

101552

DLFC 1.0 gpm for 3/4”

101556

DLFC 1.3 gpm for 3/4”

One

101559

DLFC 1.7 gpm for 3/4”

DLFC

101574

DLFC 2.2 gpm for 3/4”

must

101577

DLFC 2.7 gpm for 3/4”

be used

101583

DLFC 3.2 gpm for 3/4”

if 3/4

101588

DLFC 4.2 gpm for 3/4”

fitting

101591

DLFC 5.3 gpm for 3/4”

is used

101593

DLFC 6.5 gpm for 3/4”

101594

DLFC 7.5 gpm for 3/4”

QTy.

ITEM NO. ORDER NO. DESCRIPTION

DESCRIPTION