Operating Parameters

User Parameters

User parameters are operating parameters that can be changed

without

entering the

codes: P00 to P25

Axis assignment

Parameters which are entered separately for each axis have

axis codes

:

"1" signifies the X-axis, "2" the Y-axis, and (with the ND 550) "3" the Z-axis.

A point separates the axis code from the parameter number.

In the operating parameter list, these parameters are set off with a superscript "

A

",

the parameter for the X-axis (e.g. ) is in the list.

You select axis-specific operating parameters with the yellow arrow keys.

To call the operating parameter list:

➤

Press MOD.

To go directly to a certain operating parameter:

➤

Press and hold CL, then press the first digit of the parameter number.

➤

Release both keys and enter the second digit of the parameter number.

Protected Operating Parameters

In order to change protected operating parameters, the code number 95 148 must be

entered via P00 Code: They remain accessible until the position display is switched

off.

To page through the operating parameter list:

➤

Page forward

: press MOD.

➤

Page backward

: press the 1 / 2 key.

Any changes are automatically activated when you resume paging.

To change a parameter setting:

➤

Change the value with the minus key,

or

➤

Enter the desired value directly, e.g. for P25.

To correct an entry:

➤

Press CL.

To exit the operating parameters:

➤

Press ENT.

This activates all changes made.

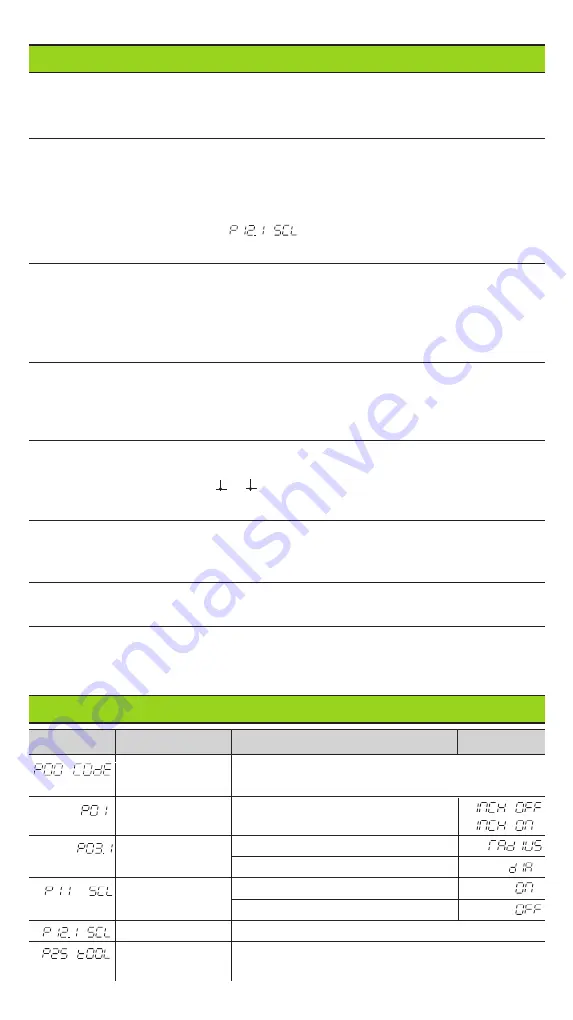

Operating Parameter List

Parameter

Meaning

Function / Effect

Setting

Code Number

95148:

protected operating parameter

105296:

select compensation value table

Unit of

Display in mm

measurement

Display in Zoll

Radius-/diameter

Rad

ius

display

A

Dia

meter

Scaling factor

Scaling factor on

Sc

a

l

ing

Scaling factor off

Scaling factor

A

Enter value for each axis separately

Tool diameter

Enter tool diameter

Tool