HEIDENHAIN iTNC 530

89

3.2 Cr

eating and W

riting Pr

ogr

a

ms

3.2 Creating and Writing Programs

Organization of an NC program in DIN/ISO

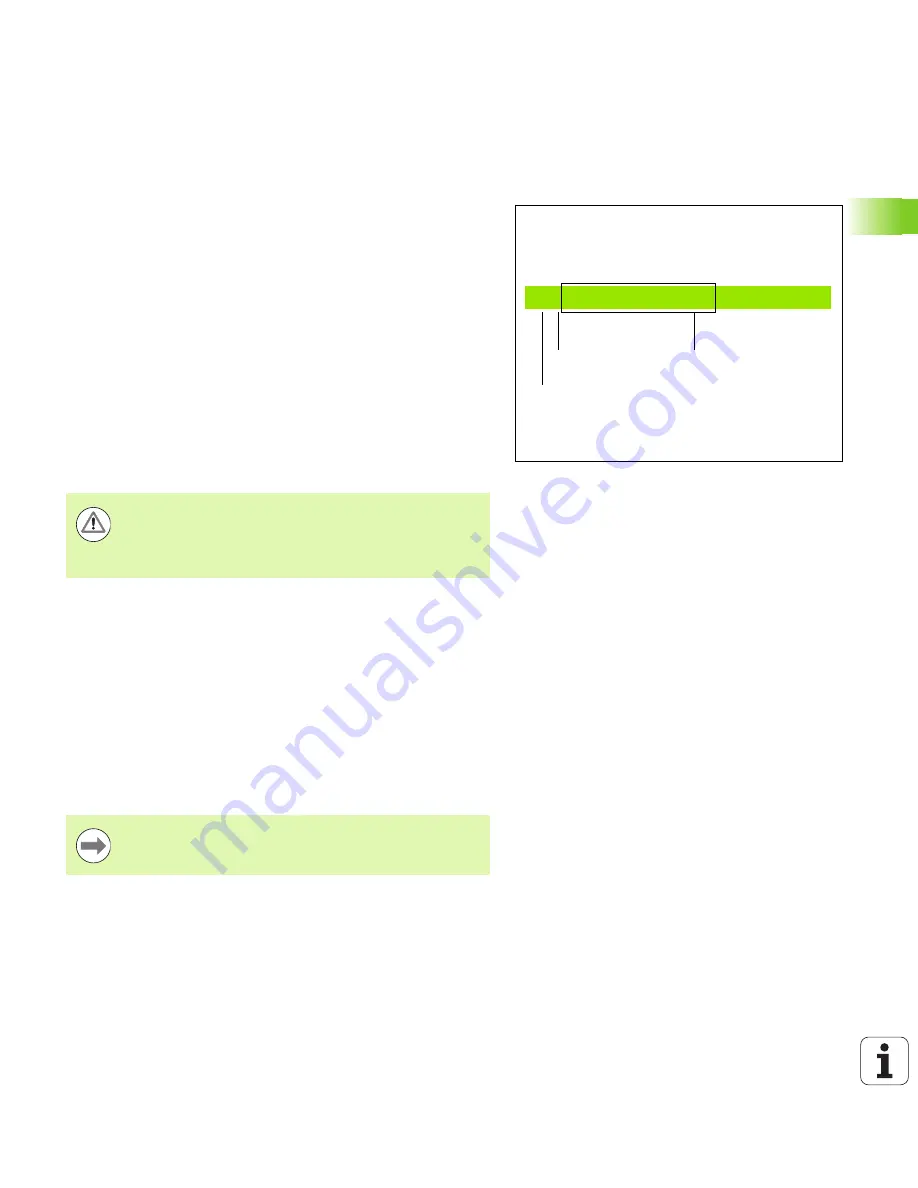

A part program consists of a series of program blocks. The figure at

right illustrates the elements of a block.

The TNC numbers the blocks of a part program automatically

depending on MP7220. MP7220 defines the block number increment.

The first block of a program is identified by

%

, the program name and

the active unit of measure.

The subsequent blocks contain information on:

The workpiece blank

Tool calls

Approaching a safe position

Feed rates and spindle speeds, as well as

Path contours, cycles and other functions

The last block of a program is identified by

N99999999

the program

name and the active unit of measure.

Define the blank: G30/G31

Immediately after initiating a new program, you define a cuboid

workpiece blank. If you wish to define the blank at a later stage, press

the SPEC FCT key and then the BLK FORM soft key. This definition is

needed for the TNC’s graphic simulation feature. The sides of the

workpiece blank lie parallel to the X, Y and Z axes and can be up to 100

000 mm long. The blank form is defined by two of its corner points:

MIN point G30: the smallest X, Y and Z coordinates of the blank

form, entered as absolute values

MAX point G31: the largest X, Y and Z coordinates of the blank form,

entered as absolute or incremental values

N10 G00 G40 X+10 Y+5 F100 M3

Block number

Path function

Words

Block

Danger of collision!

After each tool call, HEIDENHAIN recommends always

traversing to a safe position, from which the TNC can

position the tool for machining without causing a collision!

You only need to define the blank form if you wish to run

a graphic test for the program!

Summary of Contents for ITNC 530 - 6-2010 DIN-ISO PROGRAMMING

Page 1: ...User s Manual DIN ISO Programming iTNC 530 NC Software 606 420 01 606 421 01 English en 6 2010...

Page 4: ......

Page 16: ...Changed functions 606 42x 01 since the predecessor versions 340 49x 06 16...

Page 18: ......

Page 41: ...First Steps with the iTNC 530...

Page 61: ...Introduction...

Page 83: ...Programming Fundamentals File Management...

Page 130: ...130 Programming Fundamentals File Management 3 4 Working with the File Manager...

Page 131: ...Programming Programming Aids...

Page 153: ...Programming Tools...

Page 187: ...Programming Programming Contours...

Page 217: ...Programming Data Transfer from DXF Files...

Page 235: ...HEIDENHAIN iTNC 530 235 Programming Subprograms and Program Section Repeats...

Page 252: ...252 Programming Subprograms and Program Section Repeats 8 6 Programming Examples...

Page 253: ...Programming Q Parameters...

Page 301: ...Programming Miscellaneous Functions...

Page 325: ...Programming Special Functions...

Page 380: ...380 Programming Special Functions 11 8 Working with Cutting Data Tables...

Page 381: ...Programming Multiple Axis Machining...

Page 417: ...Programming Pallet Editor...

Page 437: ...Manual Operation and Setup...

Page 499: ...Positioning with Manual Data Input...

Page 505: ...Test Run and Program Run...

Page 536: ...536 Test Run and Program Run 16 7 Optional Program Run Interruption...

Page 537: ...MOD Functions...

Page 574: ...574 MOD Functions 17 21 Configuring the HR 550 FS Wireless Handwheel...

Page 575: ...Tables and Overviews...

Page 604: ...604 Tables and Overviews 18 4 Exchanging the Buffer Battery...