14

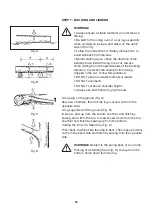

STEP 2 - ADJUST THE CHAIN TENSION

The motor must be switched off before adjusting the chain

tension.

1a. Slightly loosen the chain cover nuts.

1b. Make sure that the chain is inside the groove of the guide.

Hold the guide by its tip. Adjust the tension until the chain

teeth touch the bottom of the guide.

Turn the chain tension adjustment clockwise until the chain is

tight. Do not stretch the chain too much. Check the tension of

the chain and check if the casing is properly tightened. If this

is not the case, please repeat the procedure.

NOTE:

When tensioned correctly, it should be possible to

pull one full chain link free of the bar channel with ease. A

new chain will expand its length during the first period of use.

Check and re-adjust the tension frequently, as a loose chain

can easily derail or cause rapid wear of itself and the chain

bar.

CAUTION!

If the saw chain is TOO LOOSE or TOO TIGHT the

V-drive wheel, chain bar, chain and crank shaft bearing will

suffer premature wear. Below Fig. shows the correct tension

A (when cold) and tension B (when warm). Fig. C shows a

chain that is tooloose.

STEP 3 - FILLING WITH ENGINE FUEL

This product is powered by a 2-stroke engine and requires

premixing of petrol and 2-stroke oil. Use a high quality

2-stroke engine oil according JASO FC classic. Do not

use automotive oil or 2-stroke outboard oil. DO NOT mix

quantities larger than usable in a 30-day period.

FUEL MIXTURE: Petrol: 2-stroke engine oil = 40:1 ratio.

NOTE:

There are two faces of this bottle one is 40:1, and the

other is 25:1, please always use 40:1 for reference.

Using a funnel and keeping the bottle level, pour the petrol

firstly in the left hand side (B) up to the required level and

pour oil up to the (A) marking level. Shake vigorously to mix

the petrol and oil prior to pouring into the tank (C).

Clean the surface around the fuel cap to prevent

contamination.

Tensioner

screw

Tensioner

screw

A

B

C

D

A

B

C

D