13

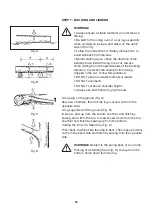

2)Install the guide and mount the chain on the pinion and

guide in the direction shown below

3)Attach the bracket and screw it in place.

4)Reinstall the chain cover in place.

5)Check if the chain is well install on the guide.

Rotate the chain with your hand to check that it is turning

without excessive resistance and that it is properly tightened.

Repeat the installation if the chain is not tight.

b.Adjusting the chain tension

The tool motor must be switched off before adjusting the

chain tension.

Make sure that the chain is inside the groove of the guide.

Hold the guide by its tip. Adjust the tension of until the chain

teeth touch the bottom of the guide.

Turn the chain tension adjustment clockwise until the chain is

tight. Do not stretch the chain too much. Check the tension of

the chain and check if the casing is properly tightened. If this

is not the case, please repeat the procedure.

STEP 1 - CHAIN BRAKE MECHANICAL TEST

WARNING!

The purpose of the chain brake is to reduce the

possibility of injury due to kickback; however, it

cannot provide the intended measure of protection

if the saw is operated carelessly.

Always test the chain brake before using your saw

and periodically while on the job.

Your chainsaw is equipped with a chain brake that reduces

the possibility of injury due to kickback. The brake is activated

if pressure is applied against the brake lever when, as in the

event of kickback, the operator’s hand strikes the lever. When

the brake is actuated, chain movement stops abruptly.

Before starting, test the chain brake by pushing it forward

until an audible click is heard.

a. The chain brake is DISENGAGED (chain can move by hand)

when the BRAKE LEVER IS PULLED BACK AND LOCKED.

b. The chain brake is ENGAGED (the chain is locked) when

the brake lever is pushed forward. It should not be possible to

move the chain by hand.

WARNING!

The brake lever should snap into both

positions. If this is not the case, do not use your

saw.

Contact the helpline immediately on 01904 727509.

b

a

b

a