28

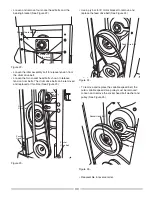

• Place the end of the belt between the clamp and drum

and tighten the socket head bolt in the clamp.

NOTE:

The drum body is spring-loaded between the drum

and end pieces. Use this feature to stretch belt tightly and

then secure belt in clamp.

• Close drum cover and secure by tightening socket head

bolt.

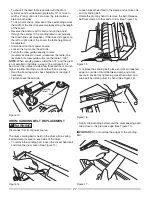

FEED BELT REPLACEMENT

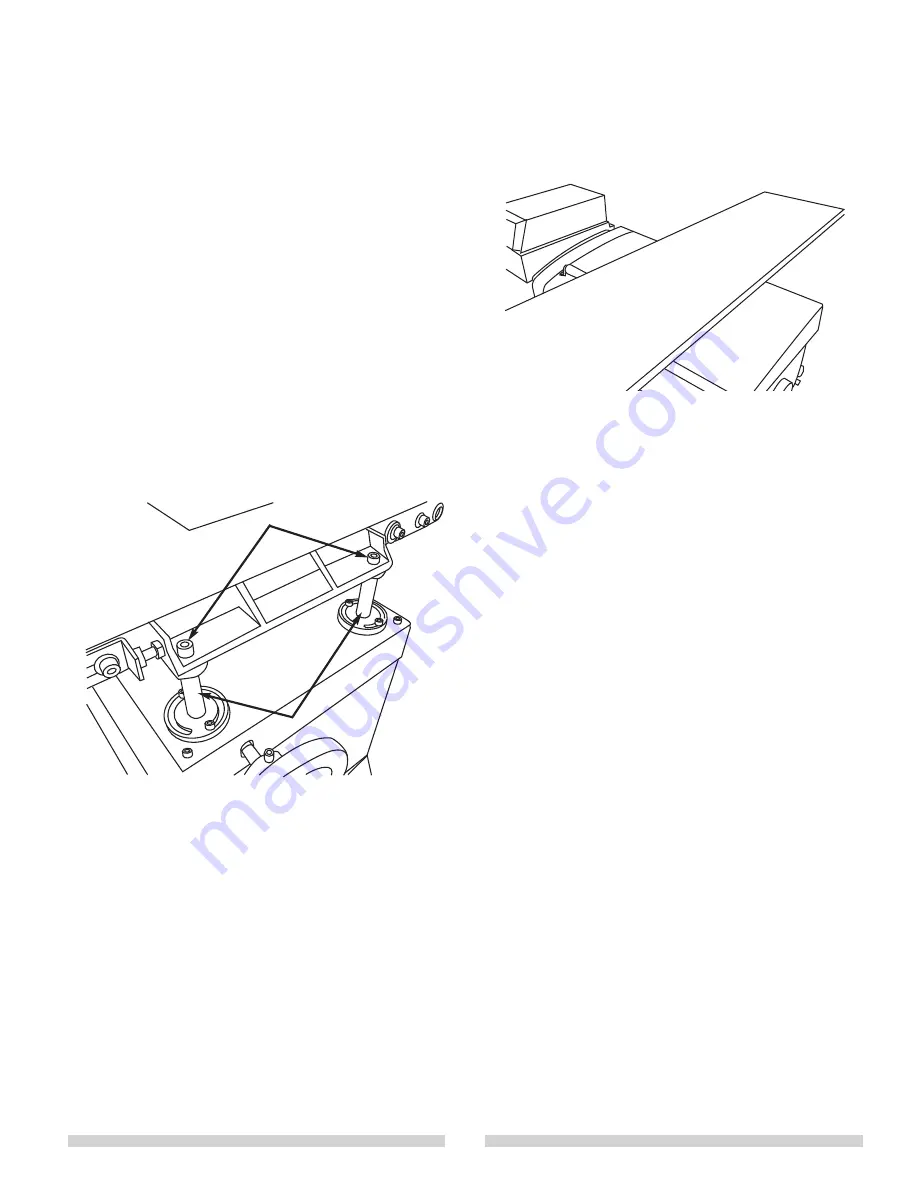

Refer to Figure 18.

• Disconnect tool from power source.

• Position table approximately halfway between drum and

base.

• Loosen and remove the socket head bolts from the two

outboard elevating screws.

• Relieve the tension on the belt; refer to “Adjusting

Tracking and Tension of Feed Belt” in the manual.

• Lift table and slide feed belt off table. Place new feed

belt on table. Apply tension to belt.

• Secure table by tightening the socket head bolts on the

elevating screws.

• Adjust tension and tracking; refer to “Adjusting Tracking

and Tension of Feed Belt” in the manual.

RETURN ROLLER

Refer to Figure 19.

The drum sander has a return roller on the drum cover so

that the workpiece can be easily moved to the front of the

sander for another pass.

SANDING BELT GRIT APPLICATIONS

• 60 grit -Used for heavy stock removal and rough

surfaces, and truing warped material.

• 80 grit - Used for general purpose sanding, stock

removal, surfacing, and rough finishing.

• 150 grit - Used for fine finishing.

• 220 grit - For very fine finishing.

For best results, sand first with a coarse grit belt, and work

toward a finer grit belt.

IMPORTANT: Sanding progression should not exceed

more than two belt grits at one time. Watch the belt for

sawdust loading and dulling of the grit. The extra load will

cause the sander to work inefficiently.

Elevating Screws

Socket Head Bolts

Figure 18 -

Figure 19 -