26

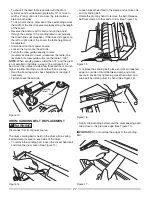

RAISING AND LOWERING THE FEED TABLE

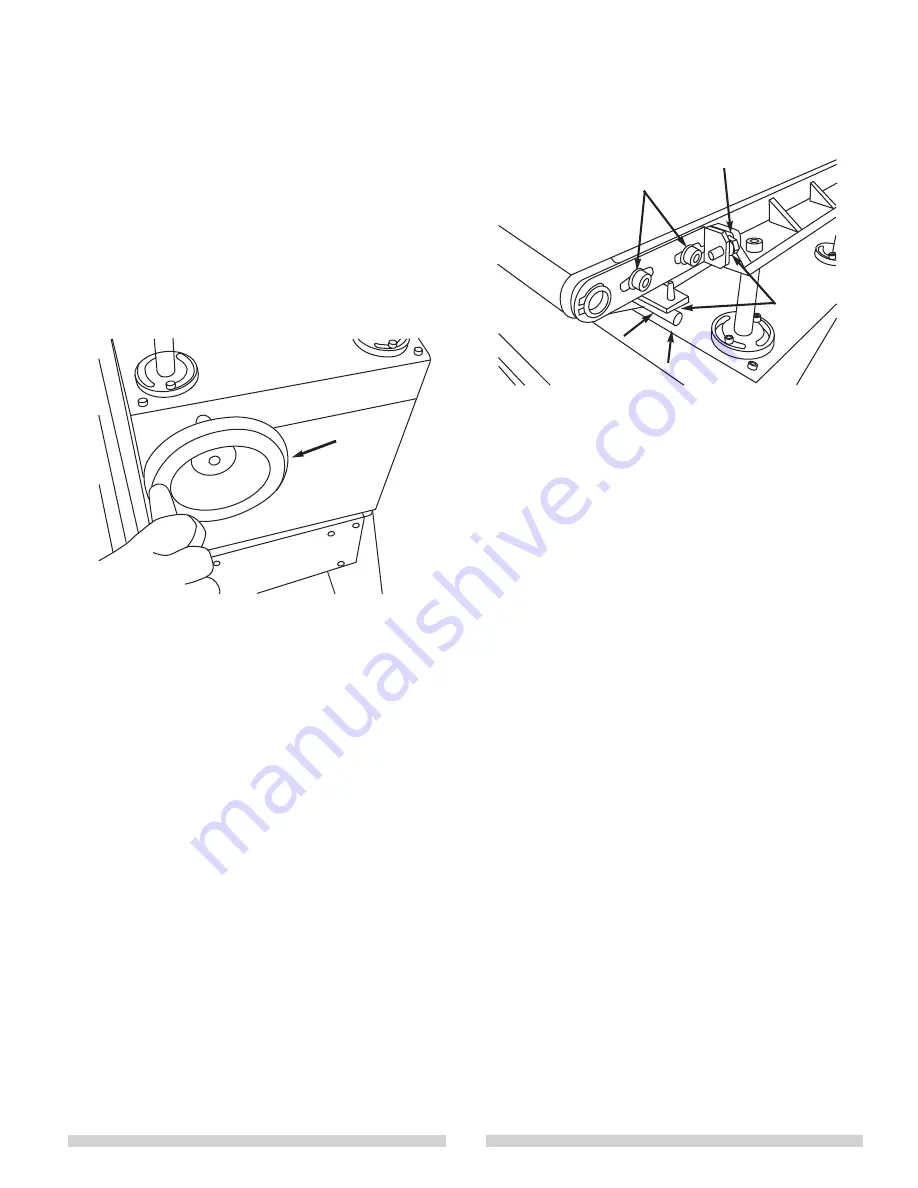

Refer to Figure 11.

• To raise the feed table, turn the handwheel clockwise.

To lower, turn handwheel counter-clockwise.

NOTE:

Each turn of the handwheel will increase or

decrease the height of the table by 1/16”.

• Stock removed settings:

1/4 turn - For material removal (1/64”)

1/8 turn - For general finishing (1/128”)

1/16 turn - For fine finishing passes

On the last finishing passes, pass the board through two

or three times to level hard spots or knots.

• Reduce depth of stock removal for wider boards and

hardwoods to prevent tripping overload protection.

ADJUSTING TRACKING AND TENSION ON

THE FEED BELT

Refer to Figure 12.

NOTE:

With a new belt, it is not unusual for one side of

the belt to be tighter than the other to make the belt track.

Frequent adjustments are normal for the first few hours of

use to allow for belt stretch. Adjustments to belt tracking

can also affect belt tension.

Belt should ride centered on the drive and idler rollers.

The drum sander is shipped with the tracking and tension

properly adjusted. However, if adjustment is necessary:

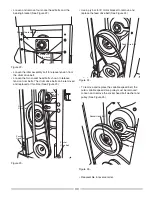

Tensioning

NOTE:

When adjusting belt tension, tighten or loosen both

bolts the same amount to avoid affecting belt tracking. DO

NOT over-tension the belt. Excessive tension will cause

premature wear of belt, bearings and overload the motor.

Listen for motor load speed changes when adjusting belt

tension.

NOTE:

Adjustments to belt tension can affect belt

tracking. Frequent adjustments are normal for the first few

hours use to allow for belt stretch.

• The belt needs adjustment if it slips on the rollers during

sanding operations.

• Loosen all four socket head bolts (A).

• Loosen hex nut. Turn both hex head bolts (B) clockwise

1/4 turn and check tension. Repeat until the feed belt is

tensioned properly. Tighten hex nuts to secure bolts in

position.

• Tighten all socket head bolts.

Tracking

• Connect tool to power source.

• Turn belt feed speed control knob to the maximum

speed, and run the feed table several minutes to check

for proper tracking of the feed belt.

• Let the belt run and observe tracking direction. If belt

does not move to either side within five minutes of

running, no adjustment is needed.

• To correct improper tracking of the feed belt to the left,

loosen the hex nut of the tracking bar assembly and turn

the socket head bolt (on the left side of the table)

counterclockwise 1/4 turn. (Counterclockwise direction

as viewed from the head of the bolt.) Continue this

adjustment until the feed belt is tracking properly on the

feed rollers. Let the feed belt run several minutes before

adjusting again. Tighten the hex nut to secure tracking

bar in position.

• To correct improper tracking of the feed belt to the right,

loosen the hex head nut of the tracking bar assembly

and turn the socket head bolt (on the right side of the

table) counterclockwise 1/4 turn. (Counterclockwise

direction as viewed from the head of the bolt.) Continue

this adjustment until the feed belt is tracking properly on

the feed rollers. Let the feed belt run several minutes

before adjusting again. Tighten the hex nut to secure

tracking bar position.

ADJUSTING FEED TABLE PARALLEL TO

DRUM

Refer to Figure 13.

The drum sander is shipped from the factory with the drum

carriage set parallel to the feed table. However, if

adjustment is necessary:

Volant

Figure 11 -

A

B

Hex Nut

Tracking

Bar

C

Figure 12 -