11

4000429690

E 11.15

US / GB

OPTIMUM 8 - OPTIMUM 1931 E

B

- Safety

Safety

1 - General safety rules

1.1 -

M

AINTENANCE

IMPLEMENTATION

Your safety and the safety of the people around are essential.

Make sure the work area is clean in order to not to pollute the system of the machine.

Before performing any maintenance interventions, place the machine in maintenance configuration.

Never leave the hydraulic cylinders fully extended or retracted before switching off the machine, or when

stationary for an extended period of time. Keep the elements of the machine in configuration of

maintenance thanks to mechanics devices.

Report that the machine is under maintenance by tagging the platform and ground control boxes.

Note :

• Using the machine during maintenance is strictly forbidden.

• Do not climb onto the covers.

• The handling of parts must be carried out using appropriate equipment (Chains, Lifting slings, Lifting

anchors).

• Plug the end of any hoses removed, and cap any open ports to prevent contamination during

maintenance.

The maintenance stand must be in place before any

maintenance operation is begun.

Placing the machine in maintenance configuration :

• Lift scissor arms to a sufficient height (floor of the platform

at around 2,5 m / 8 ft 2 in from the ground).

• Pull the plastic handle and put the stand in the vertical

position.

• Release the handle. The stand should remain in the vertical

position.

• Lower the scissor arms.

• Scissor arm pivoting rod should rest on the V groove of the

stand.

• Push the E-stop push-button to cut off the electricity supply.

Putting in use position :

• To put back the machine into its normal operation, reverse

the steps used above.

Summary of Contents for OPTIMUM 1931 E

Page 2: ...2 4000429690 E 11 15 US GB OPTIMUM 8 OPTIMUM 1931 E...

Page 10: ...10 4000429690 E 11 15 US GB OPTIMUM 8 OPTIMUM 1931 E A Preface Foreword Notes...

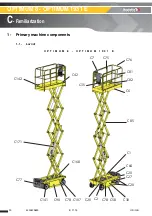

Page 19: ...19 4000429690 E 11 15 US GB OPTIMUM 8 OPTIMUM 1931 E C Familiarization Familiarization Notes...

Page 54: ...54 4000429690 E 11 15 US GB General data Structural part inspection MS0001 Notes...

Page 64: ...64 4000429690 E 11 15 US GB General data Breaking test procedure MS0004 Notes...

Page 72: ...72 4000429690 E 11 15 US GB Electric Electrical wiring MS0025 Notes...

Page 76: ...76 4000429690 E 11 15 US GB Scissor arm Scissor arms screw Periodical checks MS0073 Notes...

Page 88: ...88 4000429690 E 11 15 US GB Platform Removal replacement of platform assembly MS0095 Notes...

Page 98: ...98 4000429690 E 11 15 US GB Scissors Removal replacement of Scissor pack MS0096 Notes...

Page 102: ...102 4000429690 E 11 15 US GB Chassis Calibration steering MS0097 Notes...

Page 116: ...116 4000429690 E 11 15 US GB Ground control box HAULOTTE Activ Screen MS0106 Notes...

Page 135: ...135 4000429690 E 11 15 US GB OPTIMUM 8 OPTIMUM 1931 E E Trouble shooting and diagram...

Page 136: ...136 4000429690 E 11 15 US GB OPTIMUM 8 OPTIMUM 1931 E E Trouble shooting and diagram...

Page 138: ...138 4000429690 E 11 15 US GB OPTIMUM 8 OPTIMUM 1931 E E Trouble shooting and diagram Notes...

Page 148: ...148 4000429690 E 11 15 US GB OPTIMUM 8 OPTIMUM 1931 E F Records...