12

Operation

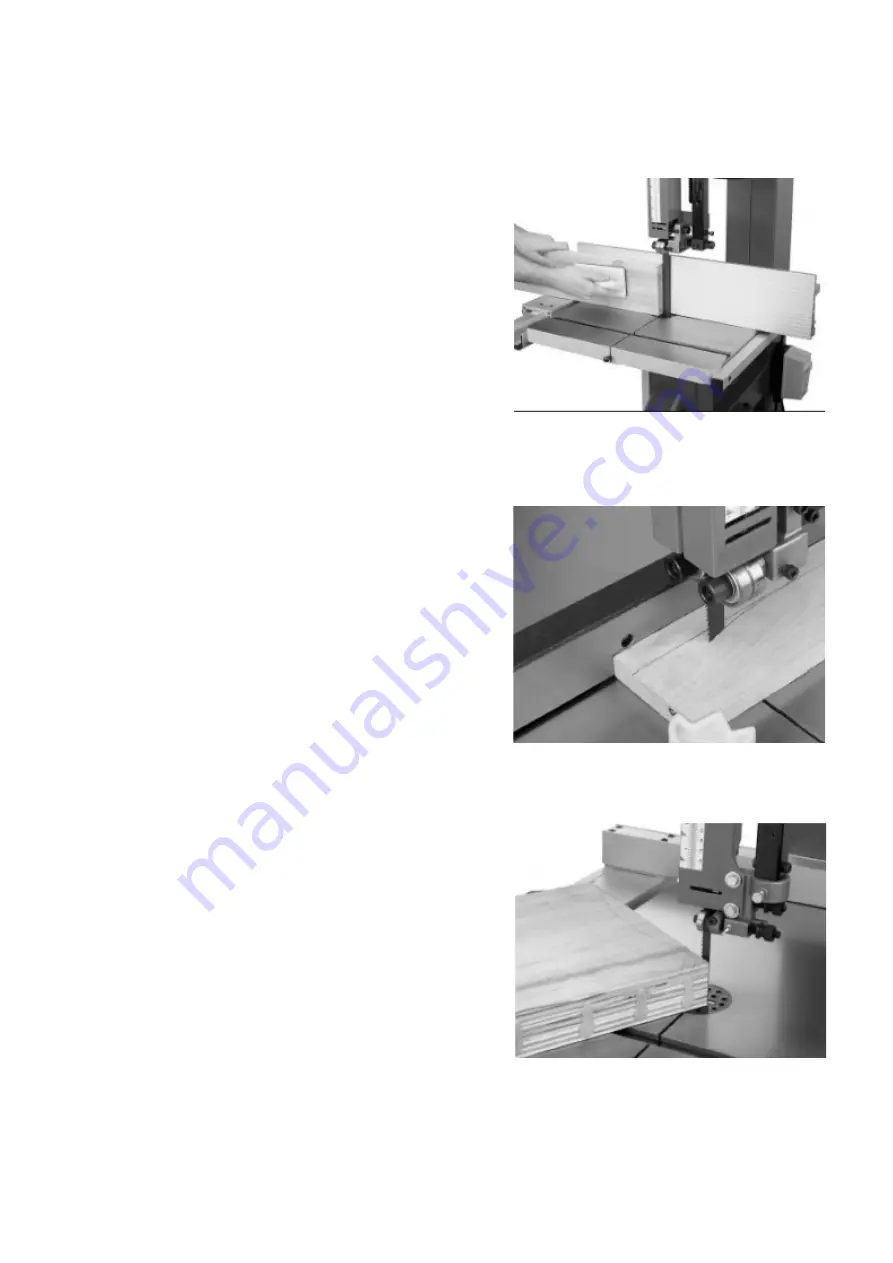

RESAWING

Re sawing is the process of cutting a board into two or

more thinner boards, the maximum board width that can be

re sawn is limited by the maxi-mum cutting height of the

band saw. One of the most important considerations when

resawing is blade selection, generally, the wider blade, the

better. In most applications, a hook or a skip tooth style

will be desirable. Choose blades with fewer teeth-per-inch,

because they offer large gullet capacities for clearing

saw-dust, reducing heat buildup and reducing strain

on the motor. In fig 19. Fig 18

CUTTING CURVES

When cutting curves, simultaneously feed and turn the

stock carefully so that the blade follows the layout line

without twisting, if a curve is so abrupt that it is necessary

to repeatedly back up and cut a new kerfs , use either a

narrower blade or a blade with more TPI (teeth per inch), or

make more relief cuts. Always make short cuts first, then

proceed to the longer cuts, relief cuts will also reduce the

chance that the blade will be pinched or twisted. Relief cuts

are cuts made through the waste portion of the work piece

and are stopped at the layout line. As you cut along the

layout line, waste wood is released from the work piece,

alleviating any pressure on the back of the blade, relief cuts Fig 19

also make backing the work piece out easier,

if needed. In fig. 20.

STACKED CUTS

One of the benefits of a band saw is its ability to

cut

multiple copies of a particular shape by stacking a number

of work pieces together. Before

making stacked cuts,

ensure that both the table

and the blade are properly

adjusted to 90, otherwise, any error will be compounded.

In

fig .21.

Fig. 20

Summary of Contents for C-18VS

Page 1: ...INSTRUCTION MANUAL Woodworking Band Saw MODEL C 18VS Harvey Industries Co Ltd...

Page 15: ...14 ASSEMBLY DRAWING...

Page 16: ...15 ASSEMBLY DRAWING...

Page 17: ...16 ASSEMBLY DRAWING...

Page 18: ...17 ASSEMBLY DRAWING...

Page 19: ...18 ASSEMBLY DRAWING...