12

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

INST

ALLA

TION

Gas Fired Boiler

13

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

INST

alla

TION

Gas Fired Boiler

Design and installation of venting

systems should be done only

by qualified and knowledgeable

venting systems personnel and

in accordance with vent system

manufacturer’s installation

instructions. Installing a boiler

or vent system using improper

installation methods or materials

can result in serious injury or

death due to fire or asphyxiation.

!

WARNING

Before connecting a boiler to a

venting system, it must be

determined whether the boiler is

to be installed in a conventional

or direct vent configuration. In the

US, provisions for combustion

and ventilation air must be in

accordance with

NFPA 54/ANSI

Z223.1

, National Fuel Gas Code,

latest edition, or applicable

provisions of the local building

codes. In Canada, combustion

and ventilation air openings shall

comply with

CAN/CSA B-149.1

Natural Gas and Propane

Installation Code.

!

WARNING

The venting materials listed are

intended for the venting of gas

burning appliances only. Do not

use these venting materials for

venting liquid or solid fuel (such

as oil, kerosene, wood or coal)

appliances.

Maintain clearances to

combustibles as listed in the

vent manufacturer’s installation

instructions or as set forth in the

codes and standards listed in this

section.

Do not use these vent pipes for

incinerators of any sort.

This boiler is not certified for

use with PVC venting. Use of

PVC venting may result in vent

failure and possible serious

injury or death.

!

WARNING

For correct installation of vent

system, read all of these

instructions and refer to vent

manufacturer’s instructions.

Failure to use a proper vent

system (types and materials),

as described in this manual will

void the boiler warranty and may

result in rapid deterioration of the

venting system, creating a health

or life safety hazard.

Faulty vent installation can allow

toxic fumes to be released into

living areas. This may cause

property damage, serious bodily

injury or death.

!

WARNING

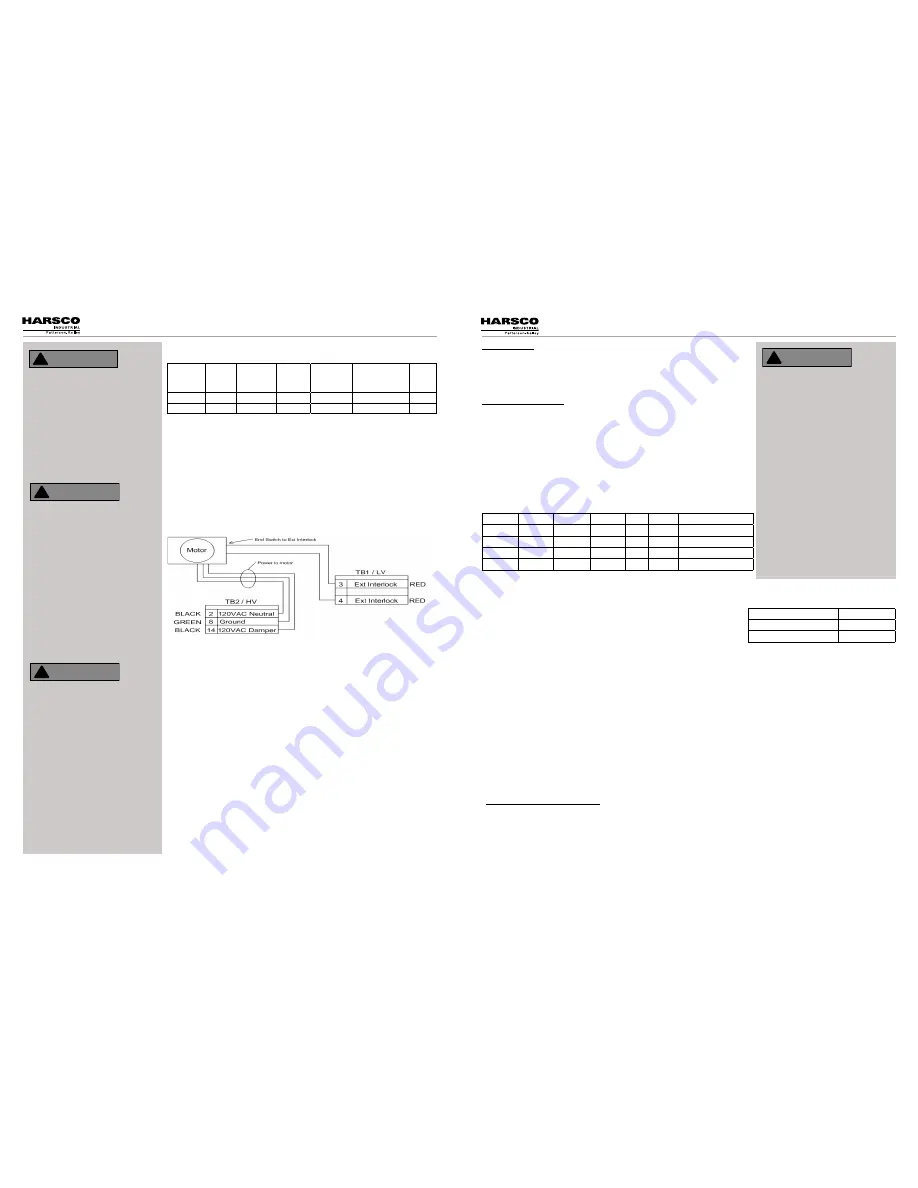

Boiler size

Nom.

vent

size

stainless

Vent

Adapter

Vent

adapter

size

Boiler

Combustion

Air inlet

Combustion air

N.C. motorized

Damper

length

SC-3000

10”

2640000133 10”

12”

1004906946

12”

SC-4000

10”

2640000133 10”

12”

1004906989

14”

Required stainless steel Vent Adapters and Category II motorized Dampers

This table is for information only. Combustion air dampers and vent

adapters are listed for use of design and may or may not be specific to

your application.

The optional, but required for Category II venting, normally-closed

motorized combustion air damper operates on 120

VAC

and features an

end limit switch wired into the boiler’s external interlock circuit. Upon a

call for heat, the boiler’s combustion air damper relay will energize and

drive the damper open. Once the damper reaches the fully-open position,

the end limit switch makes contact and closes the external interlock circuit

allowing the boiler to fire. The diagram below shows the wiring necessary

to install the normally-closed motorized damper.

3.5.1.1 Gas Vent Categories

Several codes and standards have categorized appliances in accordance

with the flue gas temperature and pressure produced by the appliance.

The applicable categories are defined as follows:

•

Category II:

An appliance that operates with a non-positive vent

static pressure and with a vent temperature that may cause excessive

condensate production in the vent.

•

Category IV:

An appliance that operates with a positive vent static

pressure and with a vent temperature that may cause excessive

condensate production in the vent.

•

Direct Vent:

An appliance that is constructed and installed so that all

air for combustion is derived directly from outdoors and all flue gases are

discharged to the outdoors.

3.5.1.2 Venting materials for Flue/exhaust systems

The

P-K SONIC™

boilers are dual certified as a Category II and Category IV

appliances, which vents with a temperature that is likely to cause condensation

in the vent. Therefore, any venting system used with the

P-K SONIC™

boiler

must comply with the requirements for either Category II or Category IV

venting systems as specified in the latest edition of

NFPA 54/ANSI Z223.1

in the

US or the latest edition of

CAN/CSA B-149.1

in Canada.

Acceptable materials for Venting systems

Manufactured Venting Systems

us and Canada:

AL29-4C Stainless Steel Vent Systems listed and labeled to UL1738 Venting Systems for Gas-Burning Appliances,

Categories II, III, and IV

316L Stainless Steel where certified and warranted by the vent manufacturer for venting of Category II, III, or IV appliances

As per ANsI Z21.13b-2012 * CsA 4.9b-2012:

•

The use of cellular core PVC, CPVC and Radel as venting materials is

prohibited.

•

The use of external insulation on plastic vent pipe is prohibited.

model

Country Al29-4C 316l ss PVC

CPVC

POlyPROPyleNe

SC-3000

US

Yes

Yes

No

Yes

Note 2

SC-4000

US

Yes

Yes

No

Yes

Note 2

SC-3000 Canada

Yes

Yes

No

Note 1

Note 1

SC-4000 Canada

Yes

Yes

No

Note 1

Note 1

Acceptable Venting materials

Note 1: When this material is used for venting, it must be listed to ULC-S636.

Note 2: When this material is used for venting, it must be listed to UL-1738.

CPVC Venting

us:

CPVC pipe conforming to ASTM F441. Sch 80 fittings conforming to ASTM

F439. Joints are to be sealed with solvent conforming ASTM 493.

Canada:

CPVC Pipe, Fitting and Sealant listed and labeled to ULC S-636

Standard for Type BH Venting Systems.

Polypropylene Venting

us and Canada:

Polypropylene such as InnoFlue from Centrotherm

or PolyPro from DuraVent or other listed manufacturers. When used, the

same manufacturer's material must be used throughout the system. It is not

permissible to use material from different manufacturers within the same system.

3.5.2 Combustion Air materials and sizes

The air intake duct can be fabricated from PVC, CPVC, single wall

galvanized steel, or other suitable materials. The duct must be rigid

enough to maintain the full required cross sectional area under all

operating conditions. Proper sealing of the intake ductwork is necessary

to prevent infiltration of air from conditioned space. Joints in PVC or CPVC must be cemented. For galvanized

duct, wrap each joint and seam with adhesive aluminum tape or other sealant. The installation of a bird screen on

the intake termination is recommended. Ensure that the screen does not become blocked with snow, ice, insects

etc. Combustion air duct should be designed with maximum 0.22” wc friction loss.

Combustion air must be free from dust, lint, etc. The presence of such materials in the air supplied to the burner

could cause nuisance "Low Air" shutdowns or premature burner failure. The boiler should not be operated during

construction while the possibility of drywall dust, demolition dust, etc. exists.

The combustion air supply must be completely free of chemical fumes which may be corrosive when burned in

the boiler. Common chemicals which must be avoided are fluorocarbons and other halogenated compounds,

most commonly present as refrigerants or solvents, such as Freon, trichloroethylene, perchloroethylene, chlorine,

etc. These chemicals, when burned, form acids which quickly attack the boiler and the boiler stack. The result is

improper combustion and premature boiler failure.

P-K sONIC™ Boiler model Required sCFm

SC-3000

629

SC-4000

839

Table 3.5.1

Table 3.5.1.2

Table 3.5.3