10

3-90-70738R9_08/13

mAINTENANCE

GRATE LINK

grATES

SHAKER

bAr

SHAKER

hANdlE

(external)

Close-up view of grate system components

Periodic and Normal Everyday Maintenance

Blower Motor- Clean periodically to remove pet hair and lint

from the intake and fan.

Grates- Keep ash pan empty.

CAUTION: BEFORE CLEANING THE CHIMNEY AND

SMOKE PIPE, BE SURE THE FIRE IS OUT AND THE

STOVE IS COOL.

Avoid Chimney Fires. On a regular schedule, check for

creosote and soot buildup in the chimney, smoke pipe, and

spiral chamber. These areas must be kept clean. Keep a

professional chimney sweep in mind.

Steel brushes are the safest for cleaning metal surfaces.

Salt solutions and some chemical cleaners may damage

the flue liner.

To clean the chimney, obtain a stiff brush with an extendable

handle. Insert the brush into the chimney from the top.

Continue brushing and sweeping downward until the entire

length of the chimney is cleaned.

After cleaning the chimney, any debris will be at the bottom

by the clean-out door. Open the clean-out and vacuum the

loose debris.

Clean the smoke pipe, from the chimney to the stove, using

a metal brush.

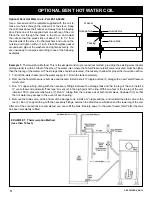

Cleaning of the spiral chamber - Remove clean-out plate

from the front of the stove. Using a 3/4” wrench, loosen the

clean-out bolt approximately 2 turns. Slide the clean-out

plate to one side and remove it from the opening. Scrape

the spiral chamber with a putty knife or similar tool. The

residue will fall down to the bottom of the chamber and can

be removed through the flue opening on the back of the

stove by means of a vacuum cleaner or a small scoop.

In the firebox, remove all ashes and vacuum the entire

firebox. Inspect and replace any cracked firebricks. Since

coal and coal ashes will draw moisture, it is important

to thoroughly clean the firebox at the end of the heating

season. Some users apply a thin coating of oil or other rust

inhibitor to the inside workings, over the summer. The main

thing is that you remove all of the ash.

Spiral Chamber Cleanout

Cleanout Plate Removed

Summary of Contents for SF 250

Page 17: ...17 3 90 70738R9_08 13 notes...