11

3-90-70738R9_08/13

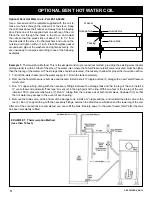

Example 1:

Thermo-siphon Method. This is the simplest and most economical method, providing the existing water heater

(storage tank) is within 10 feet of the stove. The water inlet, where the Temp/Pressure relief valve is located, must be higher

than the top leg of the water coil. The storage tank should be elevated, if necessary, to allow for proper thermo-siphon action.

1. Turn off the water heater and the water supply to it. Drain the tank completely.

2. Remove the Temp/Pressure relief valve and discard. Install a short ¾” nipple and tee (1) along with a new Temp/Pressure

relief valve.

3. Run ¾” copper tubing, along with the necessary fittings, between the storage tank and the top leg of the coil. Install a

¾” vent elbow and automatic “float type” air vent (2) in the high point of the line. Within two feet of the top leg of the coil,

install a 150 lb. pressure relief valve (7). Run ¾” tubing from the release exit of both relief valves, downward (3) so that

the hot water may escape in the event of over-heating.

4. Remove the drain valve, at the bottom of the storage tank. Install a ¾” nipple and tee, and reinstall the drain valve to the

tee (4). Run ¾” copper tubing, with the necessary fittings, between the drain/tee combination and the lower leg of the coil.

After all of the connections are completed, you can refill the tank. Restore power to the water heater ONLY after the tank

has been completely refilled.

OPTIONAl bENT hOT wATEr COIl

Optional bent hot water Coil - Part #3-10-49202

Use a hole saw and the template supplied with the coil to

make two holes through the side wall of the stove. Keep

the coil holes above the firebrick and away from the loading

door. Place one of the supplied nuts on each leg of the coil.

Place the coil through the holes in the stove, and adjust

the nuts so that the pipes stick out about 1¼” to 1½” from

the sidewall of the stove. Put flat washers and nuts on the

outside, and tighten within ¼ inch. Place fiberglass gasket

around each pipe at the washers and tighten securely. You

are now ready to run pipes according to one of the following

examples.

EXAmPlE 1: Thermo-siphon method.

(less than 10 feet.)

Outside Nut

Washer

Outside Nut

Packing

Stove Side

Summary of Contents for SF 250

Page 17: ...17 3 90 70738R9_08 13 notes...