6 - Maintenance

95

Change of tyre

Should it be necessary to replace tyres, it is recommended to leave this to a specialist and follow the mentioned rules.

1.

Always clean and inspect the rim before mounting.

2.

Always check that the rim diameter corresponds exactly to the rim diameter moulded on the tyre.

3.

Always inspect inside of the tyre for cuts, penetrating objects or other damages. Repairable damages should be

repaired before installing the tube. Tyres with unrepairable damages must never be used.

4.

Also inspect inside of the tyre for dirt or foreign bodies and remove it before installing the tube.

5.

Always use tubes of recommended size and in good condition. When fitting new tyres always fit new tubes.

6.

Before mounting, always lubricate both tyre beads and rim flange with approved lubricating agent or equivalent

anticorrosion lubricant. Never use petroleum based greases and oils because they may damage the tyre. Using the

appropriate lubricant the tyre will never slip on the rim.

7.

Always use specialised tools as recommended by the tyre supplier for mounting the tyres.

8.

Make sure that the tyre is centred and the beads are perfectly seated on the rim. Otherwise danger of bead wire tear

can occur.

9.

Inflate the tyre to 100-130 kPa (14.5-19 p.s.i.) then check whether both beds are seated perfectly on the rim. If any of

the beads do not seat correctly, deflate the assembly and re-centre the beads before starting inflation of the tyre. If the

beads are seated correctly on the rim at 100-130 kPa inflate the tyre to a maximum of 250 kPa (36 p.s.i.) until they seat

perfectly on the rim.

10.

Never exceed the maximum mounting pressure moulded on the tyre!

11.

After mounting tyres adjust inflation pressure to operation pressure recommended by the tyre manufacturer.

12.

Do not use tubes in tubeless tyres.

€

DANGER! Non observance of mounting instructions will result in the bad seating of the tyre on the rim and could

cause the tyre to burst leading to serious injury or death!

€

DANGER! Never mount or use damaged tyres or rims! Use of damaged, ruptured, distorted, welded or brazed rim is

not allowed!

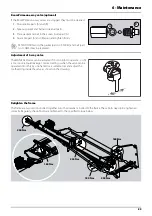

IntelliTrack front potentiometer calibration

If the IntelliTrack front potentiometer on the drawbar can not be mounted correctly (bar not perpendicular to drawbar), then

the following must be done.

1.

Align the drawbar by measuring the blank part of the hydraulic cylinder pistons. The sprayers drawbar is aligned when

the two cylinder pistons have the same length, plus/minus 2 mm. Adjust with manual track button on the HC 5500.

2.

Place the transverse potentiometer bar absolute perpendicular to the drawbar.

3.

Go to menu 4.7 in the HC 5500 and check if the potentiometer reading F is 2.50 Volt.

4.

Adjust the Potentiometer housing until the HC 5500 reads 2.50 volt.

5.

Tighten potentiometer body screws again.

€

DANGER! Be careful when operating the track! Be sure there is space enough to steer the sprayer from side to side!

Only persons working on the sprayer is allowed in the moving area of the sprayer!

Summary of Contents for NAVIGATOR DELTA

Page 4: ...1 EC Declaration 4 ...

Page 10: ...Table of Contents 10 ...

Page 14: ...2 Safety notes 14 ...

Page 32: ...3 Description 32 ...

Page 54: ...4 Sprayer setup 54 ...

Page 74: ...5 Operation 74 ...

Page 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Page 104: ...7 Fault finding 104 ...

Page 120: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...