6 - Maintenance

92

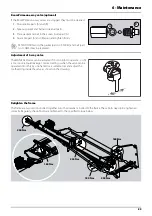

Yaw dampers renewal and adjustment

To ensure optimal damping and stability of the boom, visual control of

the yaw dampers is necessary at regular intervals.

Inspect that the yaw dampers are:

A.

Intact (If not, they must be renewed).

B.

In a tight position (If not, they must be tightened).

A - Renewal of yaw dampers:

1.

Unfold the boom

•

To get access to the yaw dampers, the position of the two cylinders

on the centre section must be altered:

2.

Remove the bolt (A). The cylinders can now be pushed aside.

3.

Screw counter nut (C) inwards and position it against the jag nut

(D).

4.

Loosen and remove nut (E).

5.

Loosen and remove nut (F), and remove the bolt - on which (F) was

situated - from below. Lift the whole profile part (G) out, to give full

access to the yaw dampers.

6.

Remove the shaft containing the yaw damper.

7.

Fasten the shaft in e.g. a jig.

8.

Loosen and remove jag nut (D) and counter nut (C).

9.

Unscrew the yaw damper from the shaft and replace it with a new one. Grease the top of the new damper.

10.

Place the jag nut (D) on the shaft again and fasten it against the new rubber damper. Also fit counter nut (C) on the

shaft again.

11.

Reassemble in reverse order. Remember to position the nut (C) against the profile now.

12.

Carry out the same procedure at the opposite rubber damper.

•

Subsequently, the yaw dampers must be equally tightened.

B - Tightening the yaw dampers:

The two yaw dampers are tightened as follows:

1.

Loosen nut E.

2.

Retain nut C against the profile by a spanner while adjusting the

bolt head I until the yaw damper is fastened.

3.

Tighten nut E against the profile again.

μ

ATTENTION! The two yaw dampers must be equally tightened.

Therefore, control that the distance between plate (H) and the

profile is 68 mm for both dampers.

Summary of Contents for NAVIGATOR DELTA

Page 4: ...1 EC Declaration 4 ...

Page 10: ...Table of Contents 10 ...

Page 14: ...2 Safety notes 14 ...

Page 32: ...3 Description 32 ...

Page 54: ...4 Sprayer setup 54 ...

Page 74: ...5 Operation 74 ...

Page 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Page 104: ...7 Fault finding 104 ...

Page 120: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...