5 - Operation

67

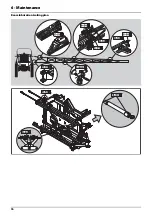

TurboFiller rinsing

Rinsing the TurboFiller and chemical containers are done in the

following two ways:

When TurboFiller lid is open

For cleaning empty containers. Put container over the rotating flushing

nozzle in the middle of the TurboFiller so that the nozzle is inside the

container. Press the Chemical Container Cleaning lever and the

TurboFiller suction valve at the same time to activate the flushing nozzle

in the middle of the TurboFiller and empty out the TurboFiller rinsing

liquid.

When TurboFiller lid is closed

Use the Chemical Container Cleaning lever to rinse the hopper after filling of chemicals has ended. Press the Chemical

Container Cleaning lever and the TurboFiller suction valve at the same time to activate the flushing nozzle in the middle of

the TurboFiller and empty out the TurboFiller rinsing liquid. Do this 3 times and after the last flushing open the lid to inspect

if the TurboFiller is empty. If not, close the lid again and press the TurboFiller suction valve until the TurboFiller is empty.

μ

ATTENTION! The TurboFiller needs to be cleaned thoroughly after finishing spraying again to be sure it is clean before

spraying other crops that may be sensitive to the chemicals just used. See section “Cleaning” on page 69 for details.

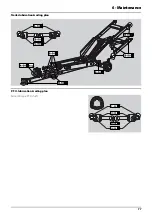

BoomPrime (optional)

The BoomPrime system works automatically, and is activated when a spray job is prepared:

1.

Unfold the boom and turn on the P.T.O.

2.

Set pressure SmartValve to “Spraying”, suction valve to “Main tank”

and agitation valve to “Agitation”.

3.

Adjust the spray pressure to what will be used when spraying.

4.

The boom will then be fully primed within 1-2 minutes.

If the nozzles start to leak when closing one or more sections during a

spray job, do as follows in mentioned order:

A.

Adjust the pressure on the BoomPrime pressure regulation.

B.

Turn Pressure SmartValve to “Main tank”.

C.

Disconnect the P.T.O.

If adjustment of the BoomPrime system might be necessary, please refer to “BoomPrime adjustment (optional)” on page 46.

Summary of Contents for NAVIGATOR DELTA

Page 4: ...1 EC Declaration 4 ...

Page 10: ...Table of Contents 10 ...

Page 14: ...2 Safety notes 14 ...

Page 32: ...3 Description 32 ...

Page 54: ...4 Sprayer setup 54 ...

Page 74: ...5 Operation 74 ...

Page 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Page 104: ...7 Fault finding 104 ...

Page 120: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...