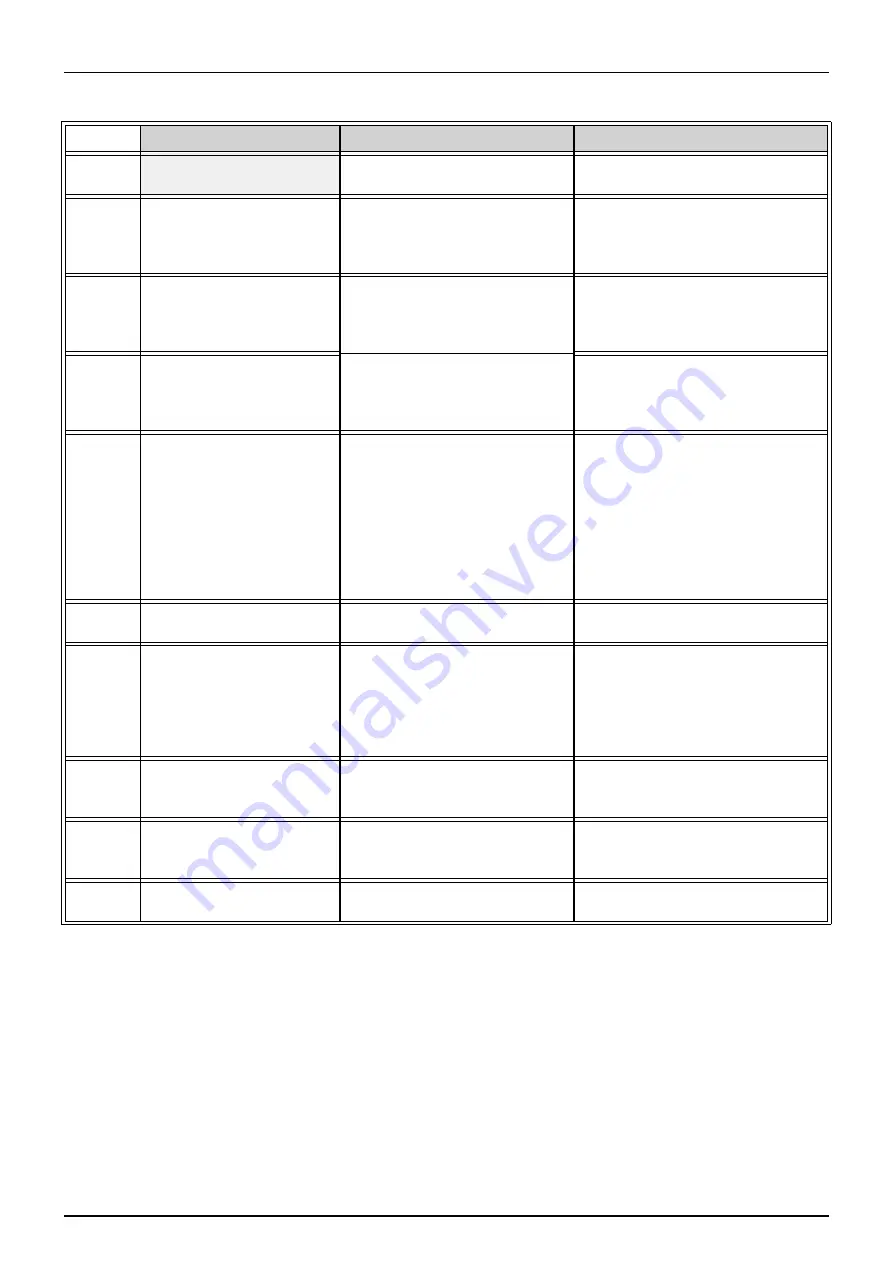

10 - Risk Assessment

10. 2

Crushing

RISK ITEM

RISK ASSESSMENT

CONTROL MEASURE

#

•

Can anyone be crushed

due to:

A

•

Material falling off the

plant

•

Yes

- If improperly secured

on sprayer

•

Operator to make sure all parts

are

properly secured – visual

inspection

required before start-

up

B

•

Uncontrolled or

unexpected movement

of the plant

•

Yes

- If improperly secured

when not in use

•

Operator to make sure sprayer is

properly

secured, park brake is

applied, remove key, lock cabin

and isolate battery.

C

•

Lack of capacity of plant

to be slowed, stopped

or immobilised

•

Yes

– if improperly

maintained

•

Make sure that sprayer is properly

maintained and brake systems

are functioning properly prior to

use.

D

•

Plant tipping or rolling

over

•

Yes

– If

it is used on

excessively inclined slopes

and if improperly controlled

by the operator

•

Use a low gear on steep inclines.

The sprayer may gather speed

during downhill turn

manoeuvres, so reduce speed

accordingly. Operator to make

sure the sprayer is operated at a

safe turning speed, taking into

consideration field conditions

and terrain.

•

E

•

Parts of the plant

collapsing

•

Yes

– If fasteners are not

tightened to specifications

•

Periodic checking of all

fasteners (Bolts & Nuts etc)

F

•

Coming in contact with

moving parts of the

plant

•

Yes

– If in contact with an

exposed

shaft, wheels or

boom when in motion

•

Operator to make sure

appropriate

guards are in place

and not allow anyone near the

boom or wheels when in

motion.

Never place fingers in

breakaway claws

•

Yes

– breakaway claws on

boom

G

•

Thrown off or under the

plant

•

Yes

– If standing on the

sprayer or ladder while it is in

motion

•

Do not allow passengers to ride

on the

sprayer, platform or

ladder when it is in motion.

H

•

Being trapped between

the plant & materials of

fixed structure

•

YES

–

If on or near the sprayer

while it is in operation

.

•

Operator should make sure no

one is in area when sprayer is

moving.

I

•

Other factors not

mentioned

No

Summary of Contents for Mercury Covamax series

Page 1: ...MERCURY COVAMAX Operator Instruction Manual 67002404 100 HAU 08 2009 www hardi com au...

Page 10: ...Table of Contents TOC 8...

Page 18: ...2 Safety 2 6...

Page 88: ...6 Maintenance 1 18 Maintenance Activity Record Date Service Performed...

Page 92: ...7 Fault Finding 1 4...

Page 100: ...8 Technical Specifications 8 8...