51

6 - Maintenance

Lubrication

General info

Always store lubricants clean, dry and cool - preferably at a constant temperature - to avoid contamination from dirt and

condensed water. Keep oil filling jugs, hoppers and grease guns clean, and clean the lubricating points thoroughly before

lubricating. Avoid skin contact with oil products for longer periods.

Always follow the quantity recommendations. If no quantity is recommended, feed lubricator till new grease becomes

visible.

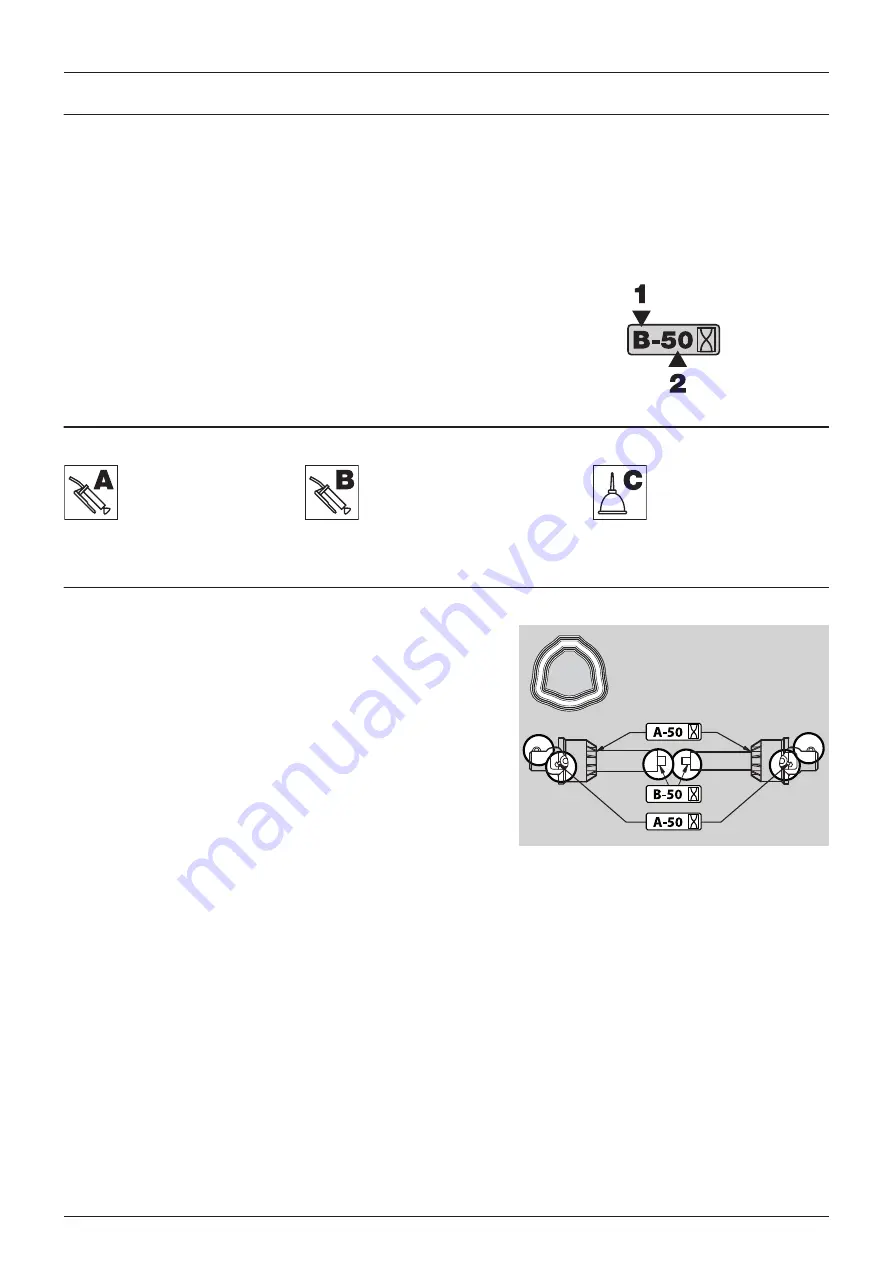

Pictograms in lubrication & oiling plans designate the following:

1.

Lubricant to be used (see “Recommended lubricants”).

2.

Recommended intervals (hours).

μ

ATTENTION! If the sprayer is cleaned with a high pressure cleaner,

lubrication of the entire machine is recommended.

Recommended lubricants

P.T.O. lubrication & oiling plan

Serie 100 type P.T.O. shaft

BALL BEARINGS:

Universal Lithium grease,

NLGI No. 2

SHELL RETINAX EP2

CASTROL LMX GREASE

SLIDE BEARINGS & GLIDE SHOES:

Lithium grease with

Molybdenumdisulphide or

graphite

SHELL RETINAX HD 2 (or HDX 2)

OIL LUB. POINTS:

TOTAL Transmission TM

SAE 80W/90

Castrol EPX 80W/90

SHELL Spirax 80W/90

Mobil Mobilube 80W/90

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...