4 - Sprayer setup

33

8.

Turn the adjusting screw for the corresponding valve until the pressure gauge shows the same pressure as when all

sections were open.

9.

Open the section valve again.

10.

Adjust the next section valves in the same way.

μ

ATTENTION! HEREAFTER ADJUSTMENT OF PRESSURE EQUALIZATION WILL ONLY BE NEEDED WHEN:

1. YOU CHANGE TO NOZZLES WITH OTHER CAPACITIES

2. THE NOZZLE OUTPUT INCREASES AS THE NOZZLES WEAR

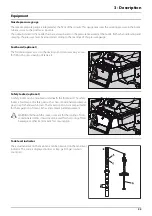

Adjustment of BK operating unit

1.

Choose the correct nozzle. Make sure that all nozzles are the same

type and capacity. See “Spray Technique” book.

2.

Open or close lever (1) depending on whether pressure agitation

is required. (Remember pressure agitation takes 5% to 10% of

pump output).

3.

Turn main ON/OFF handle (2) to ON position (A).

4.

Set all hand levers (3) on the distribution valve to ON position (A).

5.

Turn the HARDI-MATIC valve (4) anti-clockwise to its extreme

position.

6.

Put the tractor in neutral and adjust the P.T.O. thereby the number

of revolutions of the pump corresponding to the intended

travelling speed.

μ

ATTENTION! The P.T.O. revolutions must be kept between 300-600 r/min.

7.

Adjust the HARDI-MATIC valve (4) so that the pressure gauge indicates the recommended pressure.

ADJUSTMENT OF PRESSURE EQUALIZATION:

8.

Place the first lever (3) on the distribution valve in OFF position (B).

9.

Turn the adjusting screw (5) until the pressure gauge again shows the same pressure.

10.

Adjust the other sections of the distribution valve in the same way. Hereafter adjustment of pressure equalization will

only be needed if you change to nozzles of other capacities.

11.

Operating the control unit while driving: To stop the liquid flow to the boom turn the ON/OFF handle (2) to OFF

position (B). This returns the pump output to the tank through the return system. The diaphragm anti-drip valves

ensure instantaneous closing of all nozzles. To stop the liquid flow to one or more boom sections, turn lever (3) of the

distribution valve to OFF position (B) for the section to be closed. The pressure equalization ensures that the pressure

does not rise in the sections which are to remain open.

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...