7

A100h

JANUARY 2020

• MODBUS flag for warm-up is set.

• Buzzer is off.

• Relay state is “no alarm.”

• Gas reading is invalid.

3. Observe normal operation:

• Green LED is steady on.

• MODBUS flag for warm-up is cleared.

• Buzzer is off.

• Relay state is “no alarm.”

• Gas reading is valid.

The detector may also enter several special states, these

are indicated below by the specific analog output levels

indicated:

GAS DETECTOR TESTING

Field testing of the gas detector is normally done for three

reasons. The first is to determine if the gas detector is

responding to the specific gas. This test is sometimes

called a “bump” test. The frequency of the test is usually

stated in the facilities Process Safety Management (PSM)

document, but not less than every six months.

The second reason for gas detector testing is to be sure

the gas detector is properly calibrated. Depending on

the sensor element type, the sensor element sensitivity

will change with time. In particular, electrochemical

sensor elements use a material that is depleted with

time. The length of time varies depending on the amount

of exposure to the target gas, the ambient temperature

and humidity, and changes to temperature and humidity

range. Atmospheres that are very dry or very humid will

shorten the life of a sensor element.

The third reason is to be sure the gas detector

output triggers the alarms on the monitor, PLC, Gas

Alert System, horn or lights. All gas detectors are

recommended to be recalibrated at least every 6 months.

All detectors should be recalibrated immediately after

exposure to a large concentration of the target gas.

Note:

Insurance companies, local and state agencies may

require more frequent testing and calibration; refer to

insurance carrier mandates as well as local and state codes

DETECTOR BUMP TEST

A bump test is a live test of the detector to verify the

detector responds to the target gas and all connected

alarm devices are operating accordingly. Prior to test, it

is recommended all involved persons are informed about

the test as certain alarms might have to be inhibited.

1. Connect adapter and proper PPM gas cylinder to

the sensor element.

2. If desired, disable or silence audible alarms.

3. Apply a sufficiently high concentration of the

target gas to trigger alarm condition, but NOT

pure refrigerant or hydrocarbons.

MODBUS RTU RS-485 INTERFACE

For the MODBUS RS-485 network use a 16 to 24 AWG

3-core, 2 twisted pair+ ground, shielded cable with 120

ohm characteristic impedance (recommended Belden

3106A or equivalent).

The MODBUS address, baud rate, stop bit, parity and

child termination is configured through the setup menu.

No jumpers or hardware switch settings are required.

Ensure the communication parameters within the network,

including any user supplier PLC, are configured identically.

To ensure optimal performance of the MODBUS network,

ensure the following guidelines are implemented:

• Detectors are configured in a single bus topology,

connecting multiple buses in parallel or branching

multiple units from the main bus may introduce

impedance mismatches, reflections, and/or signal

distortions.

• Avoid long stubs when connecting detectors to the

bus (should be less than 3’).

• Detectors at end of bus have 120 ohm terminating

resistor enabled. Terminating resistors may be

enabled via Hansen Gas Detector App.

• A/B signal polarity is maintained throughout RS-

485 network .

• Connect cable shield to drain to physical earth or

ground at the controller only.

• Connect cable shield to (SH) terminal at sensor

• Cable shield integrity is maintained throughout RS-

485 network.

• Do not use shield connection for signal ground.

Use cable that provides dedicated ground

conductor for signal ground. Connect signal

ground to (GND) terminal of sensor.

After all wiring has been completed, power the sensor and

perform a bump test to verify instrument functionality.

START-UP SEQUENCE

After applying power, the instrument will go through a

start-up sequence (initialization, audible/visual test and

self-test sequence). After start-up sequence completes,

the instrument will enter a warm-up period to allow the

sensor element to stabilize before reporting a valid output.

1. Switch power on.

2. Observe the start-up sequence and warm-up phase:

• Green LED will blink at 0.5 HZ for about 5 minutes.

Connec4on

Descrip4on

Label

Wiring Termina4on

Power

24 VDC/VAC in

24V IN: -

24 VDC/VAC neutral/ground

24V IN: +

24 VDC posi4ve / VAC live

24 VDC/VAC out

24V OUT: -

24 VDC/VAC neutral/ground

24V OUT: +

24 VDC posi4ve / VAC live

Digital Output

Modbus Network

Communica4ons

MODBUS: B

RS-485 "B" (inverted)

MODBUS: A

RS-485 "A" (non-inverted)

MODBUS: GND

RS-485 GND

MODBUS: SH

RS-485 Shield

Analog Output

Voltage or Current

output

ANALOG: -

Analog output ground

ANALOG: +

Analog output signal (+)

NOTES:

1. Polarity must not be reversed. 2. for 24 VAC in a daisy chain configura4on, the neutral polarity must be

maintained for all instruments. 3. If analog output is configured for 4-20mA output, ensure the current loop is

connected to a sinking current loop monitor before powering on the instrument.

1

POWER & SIGNAL WIRING TABLE

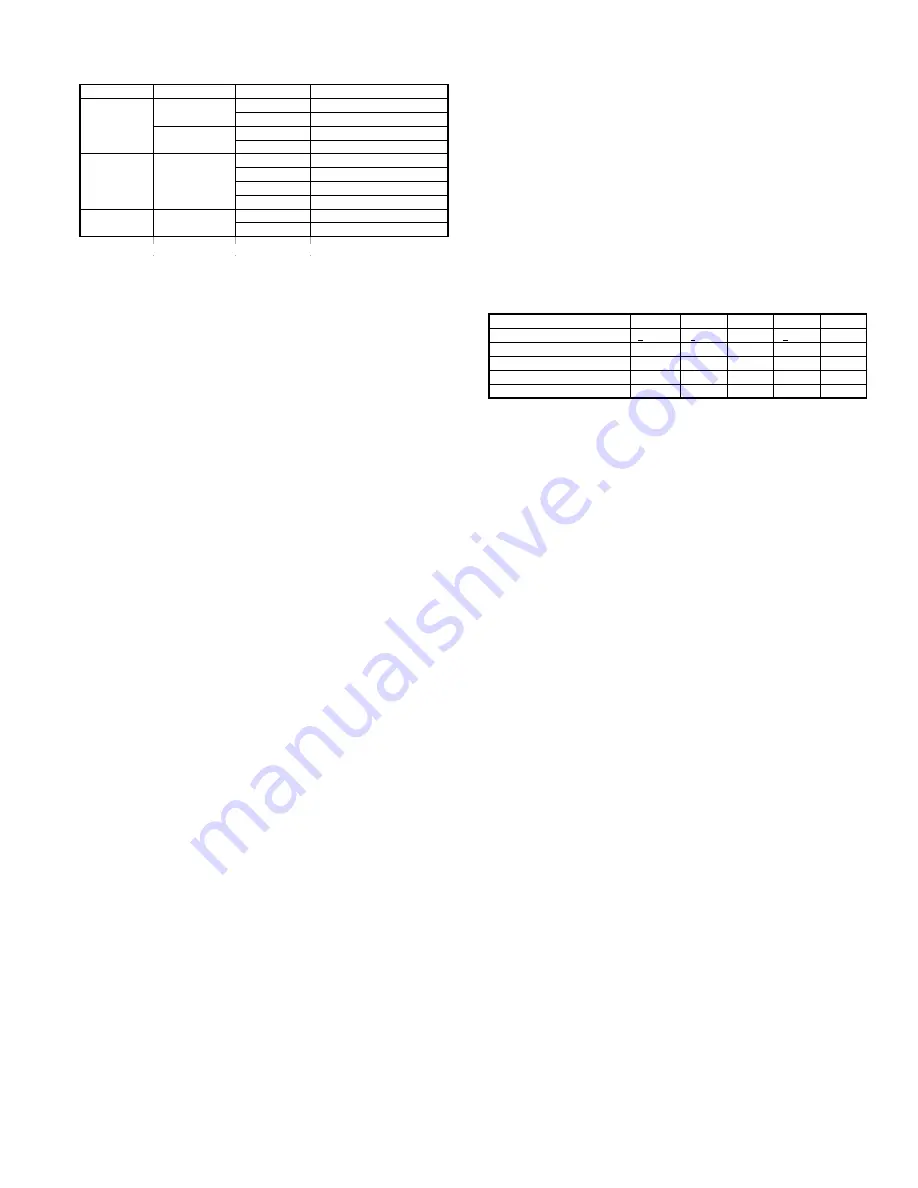

MODE OF OPERATION

4-20mA

1-5V

0-5V

2-10V

0-10V

Instrument Fault

< 1.2 mA

< 0.3 V

N/A

< 0.6 V

N/A

Offline Mode / Maintenance

3 mA

0.75 V

N/A

1.5 V

N/A

DriH below Zero

3.8 mA

0.95V

N/A

1.9 V

N/A

Measuring Range Exceeded

20.5 mA

5.12 V

5.12 V

10.25 V

10.25 V

Fault on Analog Interface

>21 mA

> 5.25 V

> 5.25 V

> 10.5 V

> 10.5 V

1

TABLE 5

TABLE 4

Connec4on

Descrip4on

Label

Wiring Termina4on

Power

24 VDC/VAC in

24V IN: -

24 VDC/VAC neutral/ground

24V IN: +

24 VDC posi4ve / VAC live

24 VDC/VAC out

24V OUT: -

24 VDC/VAC neutral/ground

24V OUT: +

24 VDC posi4ve / VAC live

Digital Output

Modbus Network

Communica4ons

MODBUS: B

RS-485 "B" (inverted)

MODBUS: A

RS-485 "A" (non-inverted)

MODBUS: GND

RS-485 GND

MODBUS: SH

RS-485 Shield

Analog Output

Voltage or Current

output

ANALOG: -

Analog output ground

ANALOG: +

Analog output signal (+)

NOTES:

1. Polarity must not be reversed. 2. for 24 VAC in a daisy chain configura4on, the neutral polarity must be

maintained for all instruments. 3. If analog output is configured for 4-20mA output, ensure the current loop is

connected to a sinking current loop monitor before powering on the instrument.

1