18

Section 8 – Elevator Linkage Installation

Required Parts

• Fuselage

• Short stabilizer tube

• Long stabilizer tube

• Stabilizer half (left and right)

Required Tools and Adhesives

• 4-40 tap

• Drill

• #4 lock washer (2)

• Clear UltraCote®

• Drill bit: #43 or 3/32" (for 4-40 tap)

• 4-40 x 1/2" socket head bolt (2)

• Aluminum servo arms (2)

• Control horn ball ends (2)

• 4

1

/

2

" 4-40 linkage (2)

The technique for installing the control horns in

the elevators is similar to the aileron control

horn installation.

Step 1

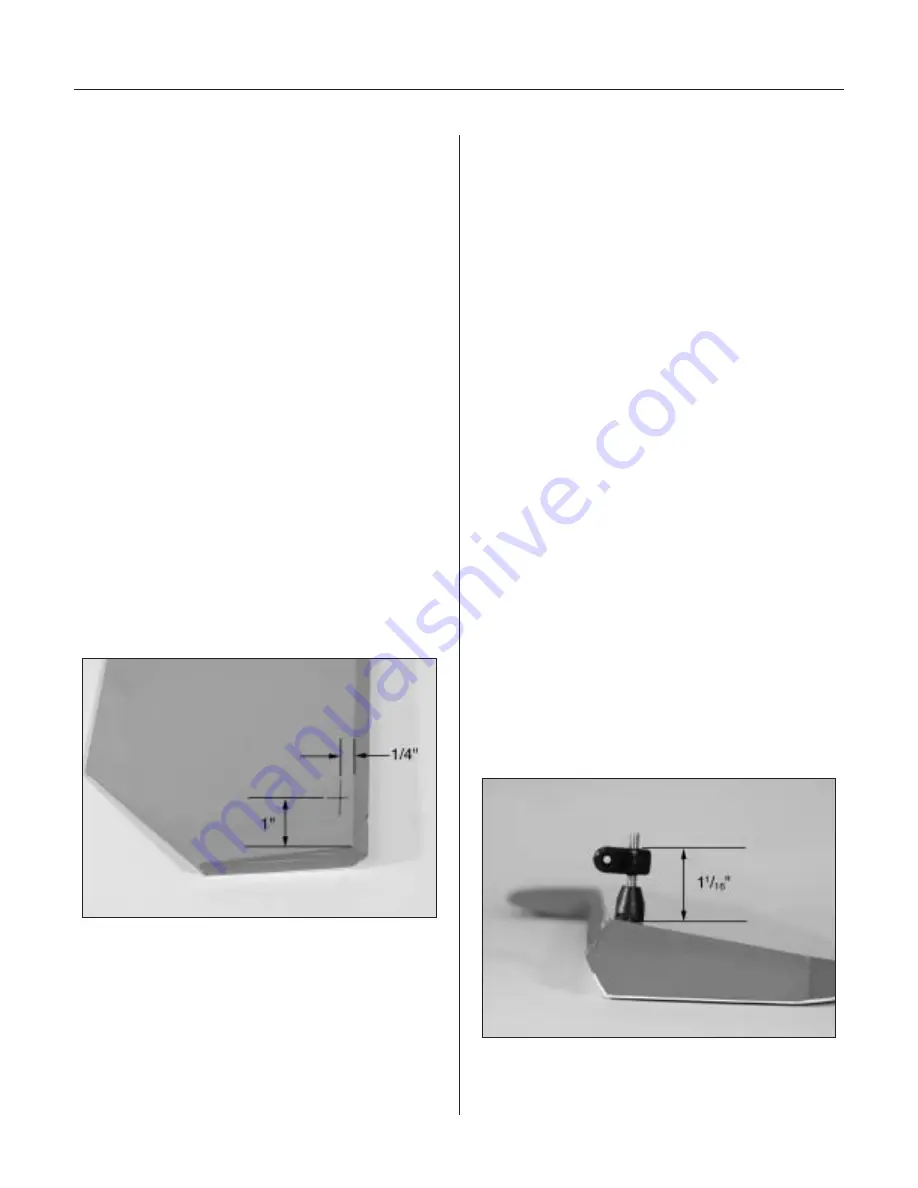

To properly locate the position of the control horn

on the bottom of the elevator, measure inward 1"

from the root and rearward 1/4" from the top of

the bevel. Mark this position on both elevators.

Step 2

Using a 5/32" drill bit and drill press, carefully drill

through the elevators at the above marked position.

It’s important to drill 90° to the top of the elevator.

Be especially careful when penetrating through the

bottom surface of the elevator, as it’s easy to split

out the wood and rip the covering. Placing a wooden

block under the elevator and drilling slowly will

prevent these problems. If you choose to use the

counter sink screws included, counter sink the

top of the elevator to allow the screws to fit flush.

Step 3

Using an 8-32 tap, thread the holes just drilled

in the elevators.

Step 4

Mix a small amount of 30-minute epoxy and lightly

coat the inside of the threaded holes and the

8-32 x 2" Hangar 9

®

screw. From the top of the

elevator, thread the 8-32 screws into the tapped

holes and tighten. Wipe away any excess epoxy

with rubbing alcohol and paper towels.

Step 5

Screw the molded swivel link onto the 8-32 screw

until the distance from the elevator surface to

the bottom of the link is 1

1

/

16

". Repeat this for

the other elevator.