13

35% Extra 300 ARF Assembly Manual

13. Apply a drop of threadlock to the servo center

screw and tighten the screw. This is the outer hole in the JR

Aluminum arm.

14. Tighten the servo arm setscrews. Move the servo

arm all the way to the front and back to access the mounting

lugs.

15. Connect the ball link to 1 1/2-inch servo arm. In

case of JR Aluminum servo arm, this is the outermost hole.

Insert the ball link screw into the ball link through the conical

spacer (flat surface facing the arm) and servo arm and then

nut.

16. With servo arm perpendicular to the center line

of the stab, use a Hangar 9 Pro-Link Wrench to adjust the

linkage so the elevator is at neutral position.

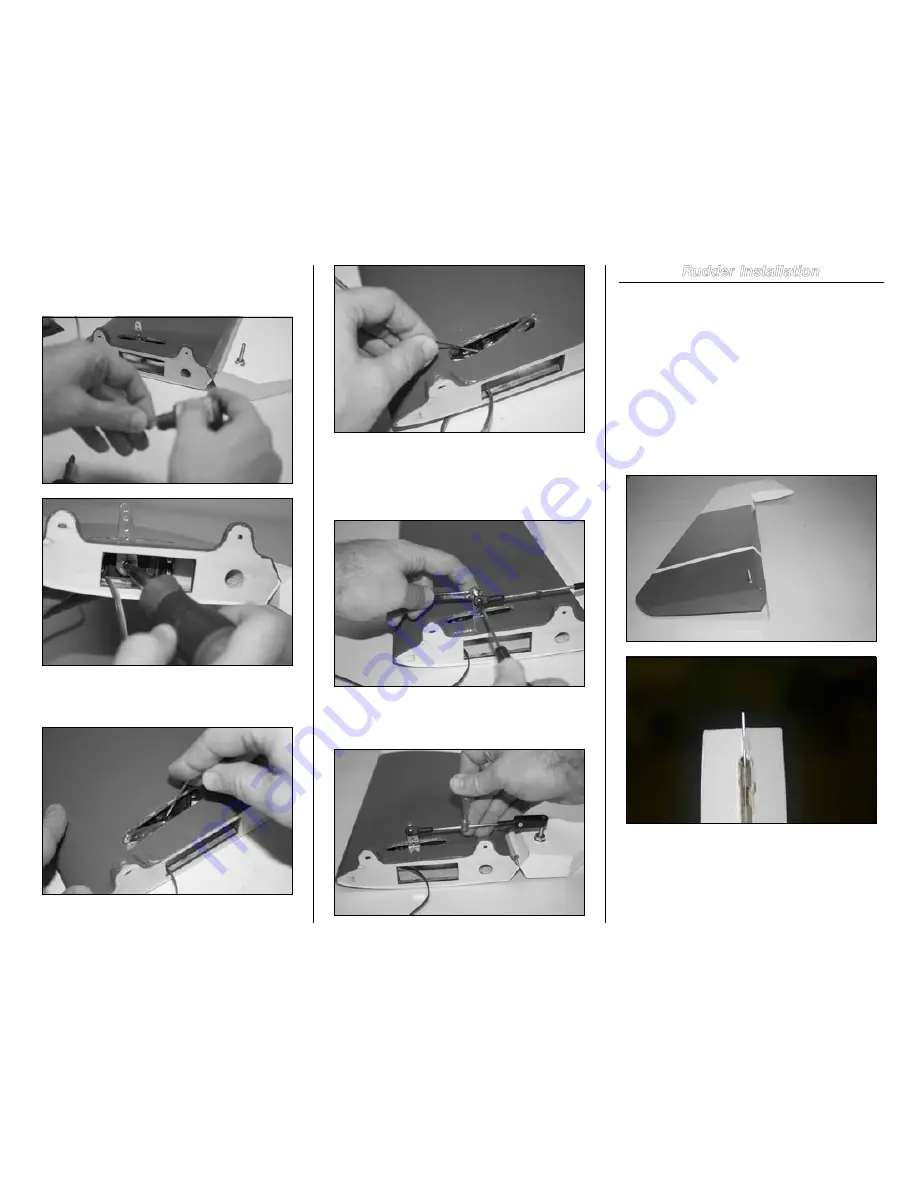

Rudder Installation

Required Parts

Fuselage

Rudder

Hinge rod

Required Tools and Adhesives

Drill

Pliers

Petroleum Jelly/Industrial lubricant

1. Apply some industrial lubricant to the rod. Pass the

rod through the hinges in the rudder and fuselage vertical fin

separately. This helps remove any possible dirt in the hinges

and makes for easier final assembly.

2. Mate the rudder and fuselage vertical stabilizer

and carefully pass the rod through hinges. This can be

accomplished by two ways. 1. Use a drill on slow speed

and gently pass through the rod. If there is any resistance,

back out and repeat. 2. Use a pair of pliers and push the rod

through the hinges. Make sure not to buckle the rod. This is

a rather slow process and needs attention.