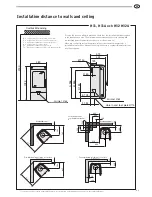

GB

65

480

Tilluftsstos Ø64

1025

2000

Brännbart tak

513

452

189

Tilluftsstos Ø64

Hål i gjuten fotplatta Ø115

A 956

B 865

D 189

C 60

E 103

F 134

Utv. Ø150

392

Brännbar vägg

150

745

817

289

Brännbar vägg

100

450

400

300

100

300

200

100

690

Tillåtet område för

brännbart material

292

Brandmur

50

645

676

239

Brandmur

50*

50

290

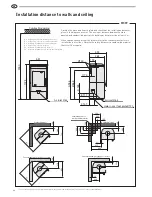

Installation distance to walls and ceiling

Position the stove on a hearth plate and check that the installation distances given

in the diagrams are met. The minimum distance between the stove opening and

combustible parts of the building or décor must be at least 1 m.

When top connecting a steel flue please refer to the relevant manufacturer’s

installation instructions. Observe the safety distances to combustible material that

steel flues require.

H31, H31A och H32 H32A

* To prevent the discolouring of painted fire walls, we recommend a side distance the same as for the combustible wall.

A = height from floor to chimney connection

B = height from floor to c/c smoke outlet rear

C = distance from back to smoke outlet rear

D = height from floor to air inlet

E= distance from back to c/c air inlet

F=

distance from back to c/c hole in cast foot plate

Combustible ceiling

Combustible wall

Fire-retardant wall of brick or concrete

Permitted area for

combustible material

.

Combustible wall

Fire-retardant wall of brick or concrete

Air inlet Ø64

Hole in cast foot plate Ø115

Air inlet Ø64