61

7.5 Important notes about applications of compressor

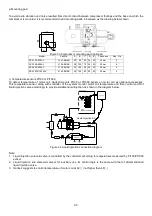

1. Pump down

Do not pump down the compressor on the chiller as a routine operation. Only pump down for urgent maintenance

or a long term shut down. Because pump down will cause extremely high temperature in the compression chamber

and overheat of the motor as well due to less amount of refrigerant in the suction side. When doing the pump down,

be sure to take notice of the items listed below:

a. Pump down should be done once each time. Repeated pump down may damage the compressor.

b. The minimum suction pressure when pumping down should is 0.5kg/cm2.

c. Time for pumping down should be shorter than 15 seconds.

d. When doing pump down, notice the high discharge temperature. It should not go over 110

℃

.

e. Notice oil level of the compressor and the sound of running as well. If there is any abnormal value or situation,

emergently stop pumping down.

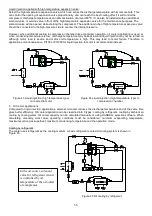

2. Low pressure receiver

When a compressor operates in the following application conditions, installation of a low pressure receiver is

recommended in order to prevent massive liquid refrigerant from returning to the compressor under momentary

changes of operation condition.

●

Heat pump

●

Parallel system

●

system with long piping

●

operating in the low ambient temperature area

●

system heating load varies extremely

Summary of Contents for RC2-AV Series

Page 15: ...4 3 RC2 AV series compressor outline drawings...

Page 16: ...15...

Page 17: ...16 UNIT SI mm Imperial in...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...

Page 28: ...27...

Page 29: ...28...

Page 30: ...29...

Page 31: ...30...

Page 32: ...31...

Page 33: ...32...

Page 34: ...33 SI mm Imperial in UNIT...

Page 35: ...34...

Page 36: ...35...

Page 37: ...36...