48

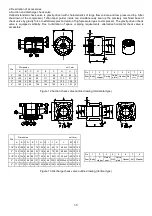

p. Mounting pad

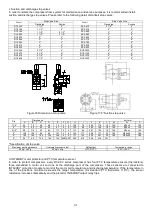

To avoid extra vibration and noise resulted from direct contact between compressor footings and the base on which the

compressor is mounted, it is recommended to add mounting pads in between as the drawing below shown.

E

A

B

C

D

Figure 33 Compressor mounting pad (optional)

Model

Part No.

A

B

C

D

E

Thickness

Req. Q’ty

RC2-100~320AV

3131-9815B

20

55

50 20 22

20 mm

4

RC2-340~580AV

3136-9815B

26 100 70 25 22

20 mm

4

RC2-620~930AV

3139-9815B

25 100 80 25 22

20 mm

4

RC2-1020~1530AV

3142-9815B

40 100 80 40 22

20 mm

4

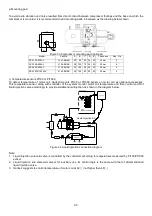

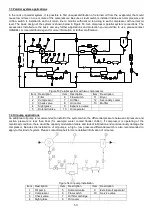

q. Temperature sensors Pt100 or Pt1000

To detect temperature of motor coil, Hanbell mounts Pt100 or Pt1000 sensor on motor coil as optional accessories.

This temperature sensor along with controller of the system monitor motor coil temperature and then control on/off of

liquid injection valve accordingly to provide suitable liquid injection as shown in the diagram below.

s

C

o

n

d

e

n

s

o

r

s

Evaporator

Dryer

Chiller

in

Chiller

out

W

U

Earth Bolt

V

B:Pt100 / Pt1000

Ω

(Optional)

A:PTC

Z

Y

X

B

A

Controller

Electric Plate

Liquid Injection S.V

Figure 34 Liquid injection connection diagram

Note:

1. Liquid injection solenoid valve is controlled by the controller according to temperatures measured by Pt100/Pt1000

sensor.

2. Liquid injection sub solenoid valve is for auxiliary use. Its control logic is the same with that of aforementioned

liquid injection valve.

3. Hanbell suggests to control temperature of motor coil at 60

(not higher than 60

)

℃

℃

Summary of Contents for RC2-AV Series

Page 15: ...4 3 RC2 AV series compressor outline drawings...

Page 16: ...15...

Page 17: ...16 UNIT SI mm Imperial in...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...

Page 28: ...27...

Page 29: ...28...

Page 30: ...29...

Page 31: ...30...

Page 32: ...31...

Page 33: ...32...

Page 34: ...33 SI mm Imperial in UNIT...

Page 35: ...34...

Page 36: ...35...

Page 37: ...36...