Hanbell Maintenance

Version 1.0

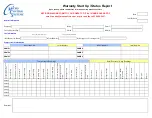

24 Month Maintenance Records

Suggestive Guidelines for Preventive Maintenance

Company _________________________________________________________________________________

Technician ______________________________________ Phone ____________________________________

Site Information

Installation Site Name _________________________________________________________________________

Unit Information - USE A SEPARATE SHEET FOR EACH COMPRESSOR

Model Number

Serial Number

Type Oil Used

Unit

Check Points

Maintenance Schedule

24

hrs

200

hrs

1000

hrs

2500

hrs

5000

hrs

10000

hrs

15000

hrs

20000

hrs

25000

hrs

30000

hrs

Motor Insulation

Oil Filter Cartridge

Suction Filter

Piston Rings

▲

PTC Sensors

Bearings

Oil Level

Oil Change

Check every 2500 hrs

Oil Analysis

Perform Oil Analysis every 6 months of constant running

Check / Clean

X

Change - add X when completed

Indicates checked or cleaned by Technicians

Item should be checked every 2500 hrs for possible contamination.

▲

Item should be replaced as maintenance schedule shows on chart above.

All given inspection and replacement intervals are only guidelines

Chiller operators should document chiller performance daily with an accurate and detailed log,

comparing this performance with design and start-up data to detect problems or inefficient con-

trol setpoints. This process allows the operator to assemble a history of operating conditions,

which can be reviewed and analyzed to determine trends and provide advanced warning of potential

problems.