26

Hampton H25 Direct Vent Freestanding Gas Stove

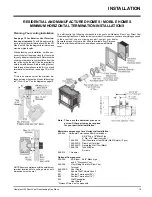

INSTALLATION

THIS CONVERSION MUST

BE DONE BY A

QUALIFIED GAS

FITTER IF IN DOUBT DO

NOT DO THIS

CONVERSION !!

GAS PIPE

PRESSURE TESTING

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.45

kPa). Disconnect piping from valve at pressures

over 1/2 psig.

The manifold pressure is controlled by a regu-

lator built into the gas control, and should be

checked at the pressure test point.

Note: To properly check gas pressure,

both inlet and manifold pressures

should be checked using the valve

pressure ports on the valve.

1)

Make sure the valve is in the "OFF" position.

2)

Loosen the "IN" and/or "OUT" pressure tap(s),

turning counterclockwise with a 1/8" wide

flat screwdriver.

3)

Attach manometer to "IN" and/or "OUT" pres-

sure tap(s) using a 5/16" ID hose.

To adjust the aeration: use the allen key to turn

the turning gear which will adjust the air shutter.

Open the air shutter for a blue flame or close it

for a more yellow flame. This adjustment is

performed by a qualified installer. The factory

setting should be sufficient for most installa-

tions.

Clockwise to open,

counter-clockwise to close.

Caution: Carbon will be produced if the

air shutter is closed too much.

Note: Any damage due to carboning re-

sulting from improperly setting

the aeration controls is NOT cov-

ered under warranty.

Note: Aeration Adjustment should only

be performed by an authorized

Hampton Installer at the time of

installation or service.

4)

Light the pilot and turn the valve to "ON"

position. Read manometer.

5)

The pressure check should be carried out

with the unit burning and the setting should

be within the limits specified on the safety

label.

6)

When finished reading manometer, turn off

the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8"

flat screwdriver.

Note: Screw should be

snug, but do not over tighten

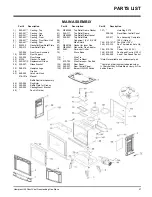

Valve Description

1)

Gas cock knob

2)

Manual high/low adjustment

3)

Pilot Adjustment

4)

Thermocouple Connection

5)

Main Operator

6)

Outlet Pressure Tap (Manifold Pressure)

7)

Inlet Pressure Tap (Supply Pressure)

8)

Pilot Outlet

9)

Main Gas Outlet

10)

Flange Securing Screw Holes

11)

Alternative TC Connection Point

12)

Thermoelectric Unit

13)

Additional Valve Mounting Hole

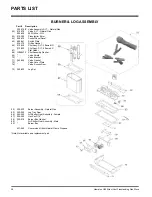

CONVERSION FROM

NATURAL GAS T O

PROPANE

Conversion Kit #431-969 Contains:

Qty. Part #

Description

1 910-018

SIT Conversion Kit-

50% Turndown LP

1 910-037

LP Injector (Pilot Orifice)

1 904-163

Burner Orifice #54

1 908-528

Red "PROPANE" label

1 908-255

Label "Converted to Propane"

1

Instruction Sheet

1) Shut off the gas supply.

2) Lift off the Cast Top and remove the glass

front (see page 35) and carefully remove

the logs and lava rock.

3) Remove burner by removing the 2 screws

on each side and then lifting the burner tray

out.

Pilot

assembly is

now accessi-

ble for steps

4) to 9).

Note: Use a magnetic type screwdriver if pos-

sible.

4) Remove and discard the 3 pressure regu-

lator mounting screws (A), pressure reg-

ulator tower (B) and diaphragm (C).

5) Insure that the rubber gasket (D) is properly

positioned and install the new HI/LO pres-

sure regulator assembly to the valve using

the new screws (E) supplied with the kit.

Tighten screws securely.

Screws