22

Hampton H25 Direct Vent Freestanding Gas Stove

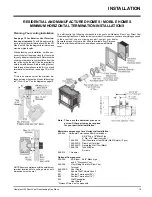

Diagram 7

DURA-VENT VERTICAL

TERMINATION

1)

Maintain the 1-1/4" clearances (air spaces)

to combustibles when passing through

ceilings, walls, roofs, enclo-

sures, attic rafter, or other

nearby combustible surfac-

es. Do not pack air spaces

with insulation. Check page

10 for the maximum vertical

rise of the venting system and

the maximum horizontal offset

limitations.

2)

Set the gas appliance in its

desired location. Drop a

plumb bob down from the ceil-

ing to the position of the appli-

ance flue exit, and mark the

location where the vent will

penetrate the ceiling. Drill a

small hole at his point. Next,

drop a plumb bob from the roof

to the hole previously

drilled in the ceiling, and

mark the spot where the

vent will penetrate the

roof. Determine if ceiling

joists, roof rafters or oth-

er framing will obstruct

Diagram 4

Diagram 3

NOTE: For Snorkel terminations in ABOVE

grade installations, follow national

or local code requirements.

Below Grade Snorkel Installation

If the Snorkel Termination must be installed

below grade, i.e. basement application,

proper drainage must be provided to pre-

vent water from entering the Snorkel Ter-

mination. Refer to Dura-Vent Installation

instructions for details.. Do not attempt to

enclose the Snorkel within the wall, or any

other type of enclosure.

4)

Install wall penetration heat shield in the

center of the 9-1/2" round hole and attach

with wood screws. The four wood screws

provided should be replaced with appropri-

ate fasteners for stucco, brick, concrete,

or other types of sidings. Dia. 3.

5)

If installing termination on a siding covered

wall, a vinyl siding standoff or furring strips

must be used to ensure that the termination

is not recessed into the siding. Dia. 3.

6)

Take the Riser Vent terminal and separate

the Backing Plate from the Riser Vent Front

by removing 8 screws as shown in dia-

gram 4.

7)

Install the Backing Plate into the wall pene-

tration heat shield and attach using 4

screws. Dia. 4.

8)

Connect all pipe sections to unit and install

into wall:

a)

Measure pipe length required and cut to

length. Hint: use the cut end of the 6-5/8" dia.

outer pipe at the vent terminal end.

b)

Push the pipe sections completely together,

the minimum pipe overlap is 1-1/4". Secure

all outer pipe joints by using at least two

screws. Locate the screws at the bottom

of the pipe so that the screw heads are

hidden on the final installation. Apply seal-

ant "Mill-Pac" to inner pipe and high temp

silicone sealant or "Mill-Pac" to outer pipe on

every joint.

Diagram 5

c)

Before connecting the vent pipe to the vent

termination, slide the black decorative wall

thimble cover over the vent pipe, then slide

the Wall Penetration Heat Shield (Part #

946-202) over the vent pipe. Dia. 3.

d)

Slide the appliance and vent assembly

towards the wall carefully inserting the

vent pipe into the riser vent terminal assem-

bly. It is important that the vent pipe extends

into the Riser Vent Backing Plate a suffi-

cient distance so as to result in a minimum

pipe overlap of 1-1/4 inches. Secure the

connection between the vent pipe and the

vent cap by attaching the two sheet metal

strips extending from the Riser Vent Back-

ing Plate into the outer wall of the vent pipe.

Use two aluminum screws provided to

connect the strips to the pipe section. Bend

any remaining portion of the sheet metal

strip back towards the vent cap and cut off

any excess, it will be concealed by the

decorative wall thimble cover. See diagram

5.

8)

Slide the decorative wall thimble up to the

wall surface being careful not to scratch

the paint. See diagram 5.

9)

Back outside: Apply sealant to the 4" inner

flue and slide the Riser Vent Front into the

Backing Plate and fasten with 8 screws.

IMPORTANT:

When connecting the pipe to the Riser

Vent, apply Mill-Pac to the inner pipe

on the Riser Vent Terminal, around

the bead. Ensure that the vent pipe is

pushed past the bead for a secure fit.

10)

Seal around the outer edge of the Riser

Vent Backing Plate.

Hint: Apply seal-

ant to female

end.

INSTALLATION