20

22

FASCIA PANEL AND CONTROLS

(CBX model shown)

23

INLET PRESSURE TEST POINT

5.3

FINAL CHECKS

a)

Turn off the appliance and remove the manometer. Tighten the

appliance inlet pressure test point screw. Re-light the burner and

test for gas tightness.

b)

Fit the appliance casing as illustrated in Figure 24. Position

and secure both side panels and the decorative front cover with

screws at the top and bottom.

c)

Fit the appliance hinged front panel in position with two

screws at the top and bottom.

d)

Set the CH Temperature Control to the required setting. Set

the room thermostat (if fitted) to the required setting. Refer to hot

water cylinder instructions.

If the boiler is connected to a hot water cylinder the

CH temperature has to be set to high.

5.4

LOCKOUT / RESET INDICATION

In the event of failure during an ignition sequence, (5 attempts)

the LED displays fault code '3'. In order to reset the boiler turn the

CH Temperature Control anticlockwise to 'STANDBY' position and

then back to 'ON' within

two

seconds.

5.5

FROST PROTECTION

The appliance is fitted with a frost protection device. In the event

of very cold conditions, the external pump may operate and the

appliance light for a few minutes to protect the appliance and

system from potential frost damage. This can only function if the

gas and electricity supplies are maintained.

e)

Ensure programmer and room thermostat (if fitted) are calling

for heat.

f)

The display changes to 'H'. The fan should start and after a

few seconds an ignition will commence.

g)

If the burner fails to light the fan will stop. Initially this may be

due to air in the gas supply line. The boiler will automatically

have five attempts at ignition. It may be necessary to turn the CH

Temperature Control knob fully anti-clockwise to reset position and

repeat (d). (See section 5.4).

h)

When the boiler has lit the display will show 'H.'. Allow the

appliance to run for at least 10 minutes and check that the gas

supply pressure measured at the appliance inlet pressure test

point is 20 ± 1 mbar for natural gas, and 37 ± 1 mbar for

propane appliances.

5.6

OVERHEAT PROTECTION

The appliance incorporates flow and return thermostats, which

monitor the operating temperature. Abnormal temperatures such

as overheating will cause the appliance to go to lockout and the

LED display will show code '1'. Allow the appliance to cool and

turn the CH Temperature Control knob fully anti-clockwise to the

reset position to clear.

5.7

OTHER FEATURES

The following additional features are included in the appliance

specification:

ANTI-CYCLE DEVICE:

When the appliance cycles on its central heating control

thermostat, a slow cycle device operates. The timer (set to 5

minutes) is activated after the end of each burn cycle to prevent

rapid cycling of the burner.

CH SOFT START DEVICE:

After every burner start the burner output stays at low for 3 minutes,

to ensure smooth heat up of the system and maximum efficiency.

SERVICE MODE:

The appliance enters the SERVICE mode by turning the control

knob fully clockwise. The LED displays a flashing 'H.'. In this

mode the appliance runs at the minimum CH output. This mode

allows the gas valve offset and CO

2

emissions to be measured.

17

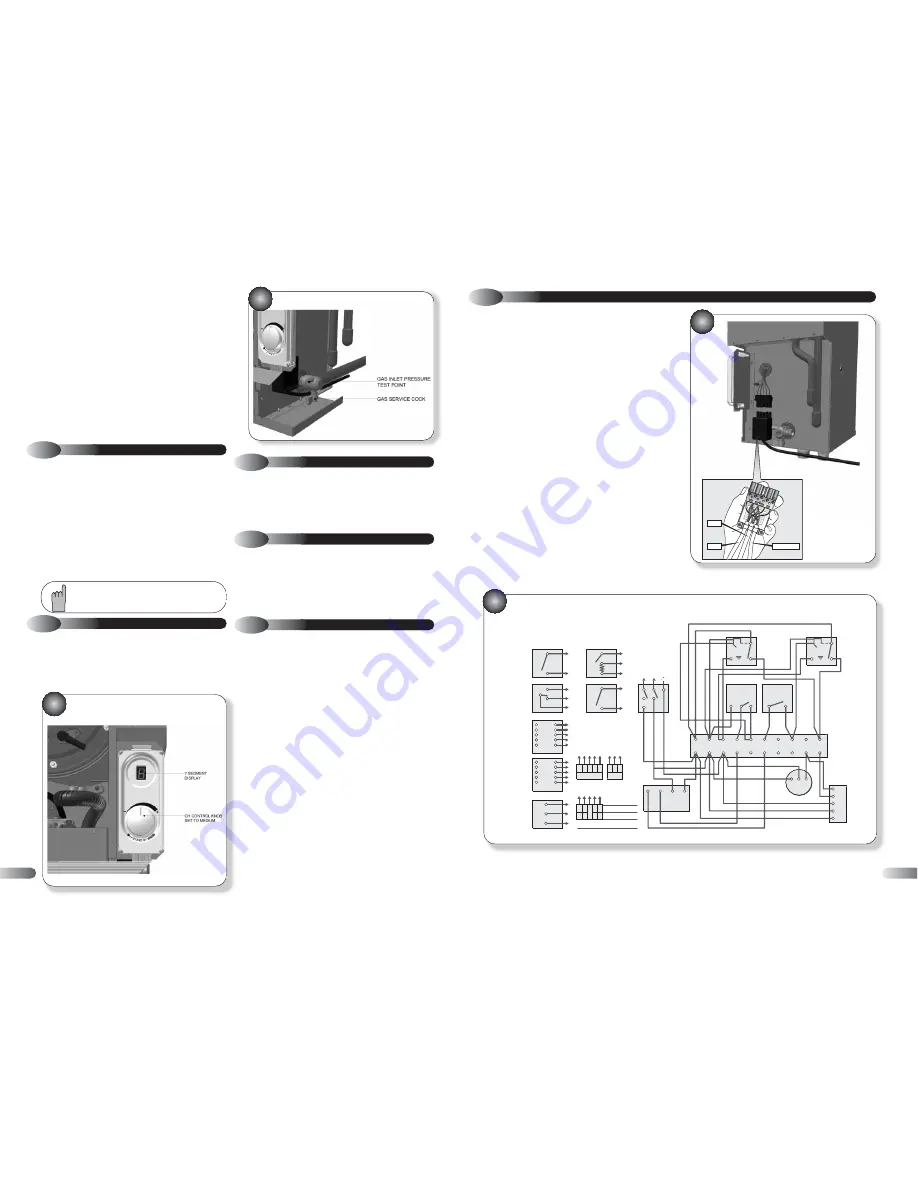

4.8

ELECTRICAL CONNECTIONS

Connect the electricity supply and external controls (using suitable

mains cable) as follows:

Wire the cable(s) into the appropriate connections in the electrical

plug provided, referring to Figure 15. Live supply to L1, Neutral

and Earth as indicated. Check that L1 and L3 are linked.

To provide correct cable retention, fit the piece of tubing supplied

over the cable as it passes through the clamping arrangement.

The cable will be held in position as the plug cover is fitted.

If a programmer/room thermostat is to be fitted remove the red

link between L1 and L3 and connect the device across these

terminals. Any external controls fitted must be rated at 230V

50Hz and have volt free contacts.

15

If using 6-wire 28mm or 1” BSPV4043H on any circuit, white is not

needed and must be made electrically safe. The wiring shown is based

on the use of 10-way junction box (Honeywell Part No. 42002116-001).

Junction Box terminal 10 is switched live and terminal 9 is pump live.

CT200

ROOM

THERMOSTAT

L641A

CYLINDER

THERMOSTAT

V4043H

HEATING

VALVE

V4043H

HOT WATER

VALVE

230V mains

input

16

Room

thermostat

Cylinder

thermostat

Heating

valve

Hot water

valve

230V

mains input

A

B

C 1

2

4

5

6

1

1

3

2

4

5

2

3

1

5

LN

8

5

910 3 2 1

9 2 3

34

5

6

7

EL

N

89

10

2

1

HW HTG N

L

2

1

10

3

8

2

1

10

3

1

2

3

Not

used

Brown

Blue

Grey

Orange

Green/

yellow

Brown

Blue

Grey

Orange

Green/

yellow

CT200

L641A

V4043H

V4043H

Programmer

Or

Time

controller

Boiler

Pump

N

E

L

63

3 4

N L

N L

Honeywell ST6998 1002

(Link L-5-3)ST 799A

2= Pump live

1=Switched live

L=Permanent live

ST6400 ST6300

ST6200

6432

21 E N L

L NE

1

Optional

T4360A

Frost thermostat

Opens heating

circuit only

T6360B

Room thermostat

230V 50Hz

Pump

Boiler

L2

L3

E

N

L1

Motor

Motor

V4043H

Zone valve

heating

V4043H

Zone valve

DHW

T6360B

Room

thermostat

L641A

Cylinder

thermostat

21

3

1

C

Brown

Grey

Grey

Blue

Blue

Green Y

ellow

Green Yellow

Brown

Orange

Orange

Fully pumped 'S' Plan

FULLY PUMPED ‘S’ PLAN

L1

L2

N

L3

MAINS

PUMP

PROGRAMMER