3.20

FILLING A SEALED WATER SYSTEM

Provision for filling the system at low level must be made, see

figure 8. There must be no permanent connection to the mains

water supply, even through a non-return valve.

CONTROLS. As a minimum it is recommended that a room

thermostat be installed to control the appliance. Thermostatic

radiator valves may be fitted to the system, however they must not

be fitted in the room where the room thermostat is fitted. There must

be at least one radiator installed with lock shield valves that should

not be closed. Further guidance can be obtained from the Domestic

Heating and Hot Water Guide to the building regulations.

13

3.21

ELECTRICITY SUPPLY

a)

Wiring external to the appliance must be in accordance with

the current I.E.E Wiring regulations (BS 7671) for electrical

installation and any local regulations, which apply.

b)

The mains cable must be at least 0.75 mm2 (24/0.2 mm)

PVC insulated to BS 6500 table 16.

c)

THIS APPLIANCE MUST BE EARTHED. Failure to provide a

satisfactory earth connection will result in appliance malfunction.

3.22

EXTERNAL CONTROLS

The VBX appliances may be used with any certified

programmer/room thermostat, as described in section 4. For

further information contact: Halstead Boilers Ltd, Service Helpline:

01926 834834.

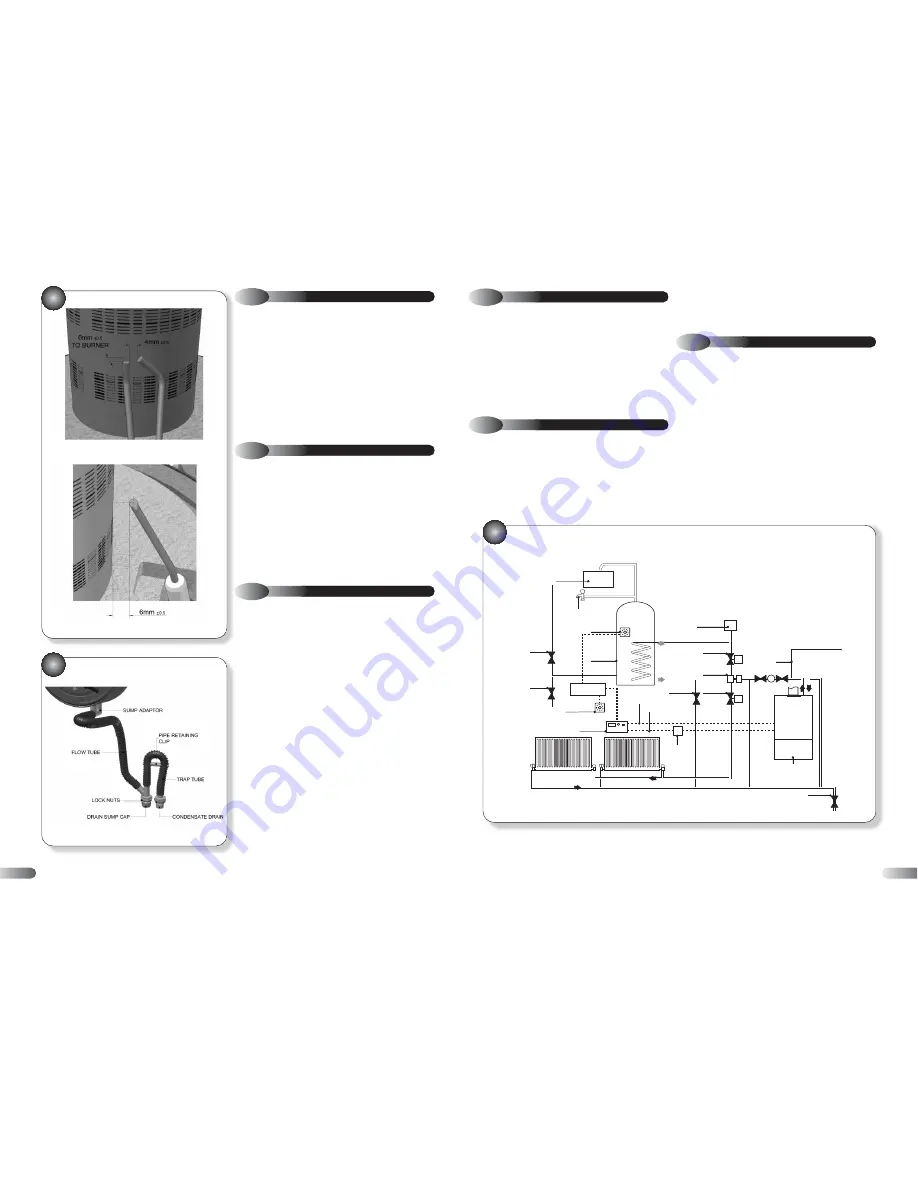

DRAIN

AUTOMATIC

AIR VENT

FLOW

RETURN

TANK

THERMOSTAT

ROOM

THERMOSTAT

TERMINAL

BLOCK

MOTORISED

VALVE

LOCKSHIELD

VALVE

STOP

VALVE

DRAIN

MOTORISED

VALVE

COLD

FEED

3-WAY

VALVE

TO DRAIN

OFF TAP

HOT WATER

CYLINDER

COLD WATER

STORAGE

APPLIANCE

CH SWITCH

DIRECT HW

CONNECT

CH/DHW

2 CHANNEL

PROGAMMER

220V RELAY BOX

(Optional)

8

OPEN WATER SYSTEM

d)

The method of connection to the mains supply must facilitate

complete electrical isolation of the appliance. Either a 3A fused

three pin plug and un-switched shuttered socket outlet, both

complying with BS 1363, or a 3A fused double pole switch

having a 3 mm contact separation in both poles and serving only

the boiler (and its external controls) may be used.

NOTE:

No automatic by-pass required. However it is

recommended to leave one radiator open and to fit a

system bypass in the DHW circuit to ensure pump over-

run functionality.

24

29A SPARK ELECTRODE

29 B DETECTOR ELECTRODE

30

CONDENSATE DRAIN

6.7

SEALED WATER SYSTEM

a)

Check the operation of the pressure relief valve as described

in section 5.1 (b).

b)

Check the correct operation of the pressure gauge by noting

the reading when cold and check that the pressure increases with

temperature. Replace the gauge if readings are suspect.

c)

Check that the system is at its original (cold) design pressure.

If necessary, re-pressurise the system as described in section 5.1

(b) and search for and rectify any leaks causing loss of water.

d)

In case of heavy pressure fluctuations during the heat and

cool down cycle, check the pre-charge pressure of the expansion

vessel. If the air pressure is less than 0.75 bar recharge vessel

with an air pump.

6.8

RE-ASSEMBLY & RE-COMMISSIONING

a)

Re-assemble all components in reverse order.

b)

Check that all joints and seals are correctly fitted.

c)

Turn on the gas and electricity supply and light the appliance,

as described in section 5.2.

d)

Re-perform a combustion check, as described in section 6.1.

e)

Check the operation of the appliance in CH mode.

f)

Remove the manometer and tighten the inlet pressure test

point sealing screw.

g)

Test for gas tightness.

6.9

FINAL CHECKS

a)

Ensure the sealed chamber door is secure with the six fixing

screws.

b)

Re-fit all decorative casing panels.

c)

Return all appliance and external controls (if fitted) to their

original settings.

29