5

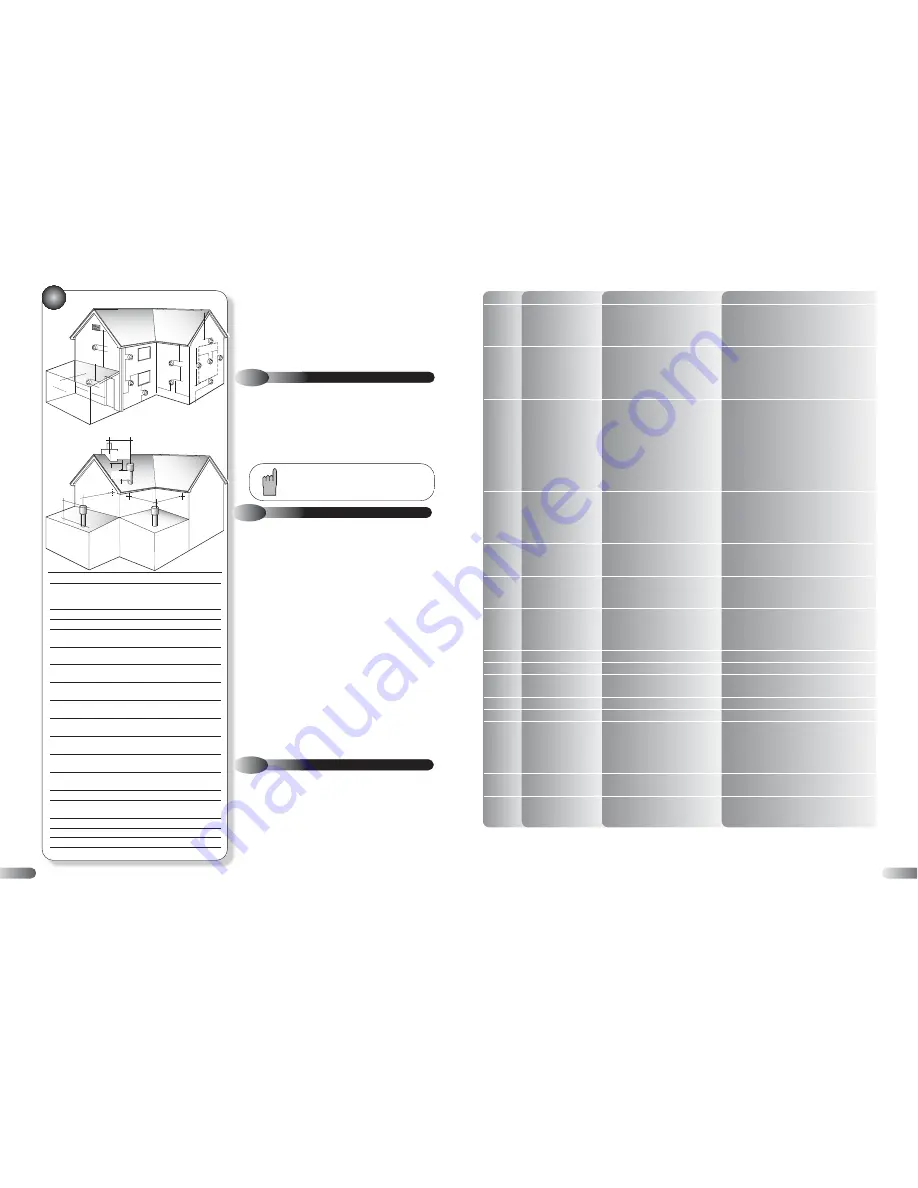

FLUE TERMINAL POSITION

Position Minimum

spacing

A

Directly below an openable window, 300mm 12in

air vent, or any other ventilation

opening

B

Below gutter, drain/soil pipe

75mm

3in

C

Below eaves

200mm

8in

D

Below a balcony

200mm

8in

*2500mm 98in

E

From vertical drain pipes and

150mm

6in

soil pipes

F

From internal or external corners

300mm 12in

*internal corners

*1000mm 40in

G

Above adjacent ground or

balcony level

300mm 12in

H

From a surface facing the terminal

600mm 24in

*2500mm 98in

I

Facing terminals

1200mm 48in

*2500mm 98in

J

From opening (door/window) in

1200mm 48in

carport into dwelling

*not recommended

K

Vertically from a terminal on the

1500mm 60in

same wall

L

Horizontally from a terminal on the

300mm 12in

same wall

M

Adjacent to opening

300mm 12in

N

Below carport

600mm 24in

*not recommended

O

From adjacent wall

300mm 12in

P

From adjacent opening window

1000mm 40in

Q

From another terminal

600mm 24in

R

Minimum height

300mm 12in

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

• •

• •

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

• •

•

•

A

B,C

G

K

M

A

E

F

F

K

B,C

G

G

K

K L

L

J

F

H,I

D,N

C

Q

O

O

P

R

SPECIAL REQUIREMENTS FOR A

VERTICALLY BALANCED FLUE

300mm

Min

430mm

Min

10

d)

If the appliance is installed in a room or internal space with other

opened flued appliances, the aggregate maximum rated input shall

be used to determine the air vent free-area. (BS 5440-2 Table 2).

e)

Where an open flued system is used, and the flue duct air

inlet is within a compartment then high and low level air vents are

necessary in the compartment, the size of the vents should be

calculated in accordance with BS 5440-2 Table 2.

3.5

CONDENSATE DISPOSAL

The condensate drain connection is suitable for either 21.5 mm or

22 mm plastic push fit or adhesive overflow pipes and fittings. It

should be piped to drain, preferably within the building, maintaining

a continuous 2.5° fall away from the appliance. If the drain is routed

to outside it should be to a drain or soak away, and any external

pipe work should be in 32 mm. Insulation to protect from freezing in

cold weather conditions is also advisable.

3.6

GAS SUPPLY

a)

The Gas Supplier should be consulted at the installation planning

stage in order to establish the availability of an adequate supply of gas.

b)

An existing service pipe MUST NOT be used without prior

consultation with the Gas Supplier.

c)

A gas meter can only be connected by the Gas Supplier or by their

contractor.

d)

An existing meter and/or pipe work should be of sufficient size to

carry the maximum appliance input plus the demand of any other

installed appliance. (BS 6891: 1988).

A minimum of 22 mm diameter pipe work is

recommended within 1000 mm of the appliance gas cock.

e)

Natural gas appliances: The governor at the meter must give a

constant outlet pressure of 20 mbar (8 in.wg) when all appliances on

the system are running.

Propane appliances: The regulator must give a constant outlet pressure

of 37 mbar (14.9 in.wg) when all appliances on the system are

running.

f)

The gas supply line should be purged. WARNING: Before purging

open all doors and windows, also extinguish any cigarettes, pipes, and

any other naked lights.

g)

The complete installation must be tested for gas tightness.

3.7

CENTRAL HEATING SYSTEM

a)

The appliances are designed for open vented central heating

water systems, but may be fitted to a sealed central heating

system provided the necessary components, such as expansion

vessel and pressure safety relief valve are fitted to the system.

Refer to Figure 8 for a typical open vented system design, which

incorporates radiators, and a drain facility that must be provided

at the lowest point in the system to allow complete drain down.

b)

The installation should be designed to operate with a flow

temperature of up to 95°C.

*Recommended by the boiler manufacturing industry to prevent

pluming nuisance and damage to buildings.

If the appliance is installed in a garage all pipe work

should be in 32 mm. Ensure that the condensate discharge

system complies with any local regulations in force.

LED CODE FAULT/EFFECT

REASON

ACTION

●

Check no air is in heat exchanger/CH system

1

Overheated appliance

Water temperature greater than 105 °C

●

Check external pump operation

●

Check PCB/X1C connector

●

Check flow thermistor

Water flow failure or

●

Check water pressure

Differential check faulty/

●

Check external pump/ CH system blockage

2

Flame for a short

Sensor temperature differential incorrect

●

Check no air is in heat exchanger/CH system

period only

●

Check flow, and return sensors

●

Check wires to sensors not crossed

●

Check gas supply

●

Check gas service cock

●

Check gas valve and lead

No gas or Lockout flame Low gas pressure.

●

Check detection electrode/lead

3

signal/ No flame, Lockout No flame signal on ignition,

●

Check gas supply

after 5 ignition attempts

or loss of signal during operation

●

Check gas valve and lead

●

Check PCB/X2A & X2B connectors

●

Check spark generator/spark electrode

●

Check mains earth lead continuity

●

Check flue sensor

●

Check flue system

4

Flue gas sensor/No flame Flue gas temperature greater than 95 °C

●

Check no air is in heat exchanger/CH system

●

Check external pump

●

Check PCB/PCB connectors

●

Check flow, return and flue sensors

5

Defective sensor/No flame Defective flow, return or flue sensor

●

Check wiring to sensors

●

Check PCB/X6 & X8 connectors

Defective gas valve/

5 sec flame signal after burner

●

Check gas valve and lead

6

Flame continues after

is switched off

●

Check PCB

demand ends

●

Check fan

7

Defective fan/No flame

Missing or Erroneous RPM signal

●

Check mains fan lead & connector

●

Check low voltage fan lead & connector

●

Check PCB/X3 connector

A

PCB error/No flame

Internal error

●

Check PCB

b

Activate BCC/No flame

New BCC

●

Turn CH control knob to reset twice to activate

C

Safety system failure/

Failure of internal self checking system

●

Check PCB

No flame

●

Check BCC is initialised

E

BCC error/No flame

Incorrect /missing BCC

●

Reseat or replace BCC

h

No flame

Faulty connector

●

Check PCB/X1A connector

●

Check water pressure

Differential check faulty/

●

Check external pump/ CH system blockage

O

Flame for 15 seconds

Water flow rate too low

●

Check no air is in heat exchanger/CH system

●

Check flow, and return sensors

●

Check wires to sensors not crossed

P

Error in power supply/

Low mains voltage

●

Check mains voltage

No flame

●

Check PCB connectors

●

Check power supply

No light indication

Defective power supply

●

Check PCB/X1B connector

●

Check PCB fuse

27