Troubleshooting

16

S/N

Possible

Malfunctions

Possible

causes

Checking Steps

Instrument

Solutions

1. Eyeball whether the cable

connectors are in position on

the computer display board.

Eyeballing

1. Insert and connect in

position. If not, please go on

with step 2.

2. Eyeball whether the electric

current breaks between cable

connectors and program

selecting board.

Eyeballing

Multimeter

2. If electric current is

broken, change the program

selecting board. If not, please

go on with step 3.

1

Time

remains the

same after

revolving the

knob; or

remains the

same on part

programs

position.

Transportati

on part of

the 5 cable

connectors

(ST4-1~ST-5)

on the

program

selecting

board is all

or partly

broken.

3. Eyeball whether the line

connecting the program

selecting board and cable

connectors connecting points

breaks.

Eyeballing

Multimeter

3. If electric current is

broken, change the program

selecting board.

1. Check the S10 and ST1

terminals on the program

selecting board, X4 and X7

terminals on the power drive

board, and ST3 terminal on

the computer display board.

Eyeballing

1. Insert and connect in

position. If not, please go on

with step 2.

2. Check whether the back

connecting points on the

program selecting board are

broken; measure and test

whether the voltage between

the two ends of ST1 is 220 V.

Eyeballing

Multimeter

2. If electric current is

broken, change the program

selecting board. If the voltage

is 220V, please go on with

step 3.

3. Check the whether the back

connecting points on the

power drive board X4 are

broken; measure and test

whether the voltage between

X4-1 and X4-2 (or between J3

and J1 on the power board) is

220 V.

Eyeballing

Multimeter

3. If electric current is

broken, change the power

drive board; if the welding

point is not broken and the

voltage between J3 and J1 is

not 220V, consider checking

whether the wiring harness

is broken; if the voltage is

220V, please go on with step

4.

4. Measure and test the

silicon control diode(1S2) pin

voltage relative to the earth on

the power drive board

:

the left

is 22V DC; the right is 5V DC.

Eyeballing

Multimeter

4. If the voltage doesn’t

comply with the requirement,

change power drive board; if

it complies with the

requirement, please go on

with step 5.

5. Measure and test X7-4 and

X7-5 terminal relative to the

X7-6 voltage

:

X7-4 is 22V DC;

X 7-5 is 5V DC.

Eyeballing

Multimeter

5. If the voltage doesn’t

comply with the requirement,

change power drive board; if

it complies with the

requirement, please go on

with step 6.

2

No sound

when

buttons

pressed; no

signal on the

display

screen.

Power

supply cable

is broken.

or

Damage of

the electric

components,

such as:

chips, silicon

control,

diode, etc.

6. Measure and test ST3-3

and ST3-2 terminal relative to

the ST3-1 voltage

:

ST3-3 is

22V DC; ST3-2 is 5V DC.

Eyeballing

Multimeter

6. If the voltage doesn’t

comply with the requirement,

change the 6 connecting

lines between X7 and ST3; if

it complies with the

requirement, please change

computer display board.

Summary of Contents for HT1006TXVE

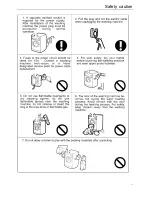

Page 6: ...Safety caution 6 ...

Page 7: ...Safety caution 7 ...

Page 8: ...Safety caution 8 ...

Page 9: ...lnstallation 9 lnstallation 9 ...

Page 10: ...Installation 10 ...

Page 11: ...Functions 11 ...

Page 12: ...Functions 12 ...

Page 13: ...Function schedule 13 ...

Page 14: ...Function schedule 14 Function schedule 14 ...

Page 15: ...Troubleshooting 15 ...

Page 19: ...Wiring circuit 19 ...

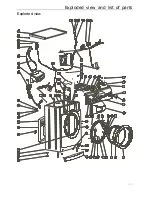

Page 20: ...Exploded view and list of parts 20 Exploded view 78 77 ...