Troubleshooting

17

S/N

Possible

Malfunctions

Possible

causes

Checking Steps

Instrument

Solutions

3

VFD screen

cannot fully

display.

Breakdown

of computer

display

board

Check whether the cable is

partly broken or whether there

is cracked, partly burnt or

etched phenomenon of all

kinds of chips.

Eyeballing

Change computer display

board.

Check whether computer

display board in position.

Eyeballing

If normal, go on with the next

step.

4

Buttons do

not work.

Breakdown

of computer

display

board

Check by hand whether the

buttons are comfortable to

press; check whether the

cables around the buttons are

broken or partly burnt or

etched, etc.

Check by

hand

Eyeballing

Change computer display

board.

1 Check whether the door is

well closed.

Eyeballing

If normal, go on with the next

step.

2. Check whether the door

lock is well linked.

Eyeballing

If normal, go on with the next

step.

3. Check whether the door

lock is damaged.

Eyeballing

Multimeter

If normal, go on with the next

step.

5

Err1 Alarm

Breakdown

of computer

display

board.

or

Breakdown

of power

drive board.

4. Check whether the relevant

wiring harness is broken.

(esp. the connecting line from

computer display board to

power drive board as well as

the lock cable. )

Eyeballing

Multimeter

If normal, change computer

display board or power drive

board. Check which board

goes wrong in an exchanging

way. In case of Err1 Alarm,

the quality computer display

board and power drive board

are expected to be taken

before the user is served to

make it easy to check.

1. Check whether the

drainage pump is blocked.

Eyeballing

If normal, go on with the next

step.

2. Check whether the

drainage pump is damaged.

Multimeter

If normal, go on with the next

step.

3. Check whether the

pressure switch hose or

gas-collecting valve is

blocked.

Check by

hand

Eyeballing

blowing

If normal, go on with the next

step.

4. Check whether the

pressure switch is damaged.

Eyeballing

Multimeter

If normal, go on with the next

step.

6 Err2

Alarm

The water is

not drained

completely

(The water

switch does

not return to

normal.)

5. Check whether the relevant

wiring harness is broken.

Eyeballing

Multimeter

If normal, change power

drive board.

1. Check whether sensor is

well linked.

Eyeballing

If normal, go on with the next

step.

2. Check whether temperature

sensor is damaged.

Multimeter

If normal, go on with the next

step.

7 Err3

Alarm

Temperature

sensor

resistance is

over 2

Ω

.

3. Check whether the relevant

wiring harness is broken.

Eyeballing

Multimeter

If normal, change power

drive board.

1. Check whether the heating

element is well linked.

Eyeballing

If normal, go on with the next

step.

2. Check whether the heating

element is damaged.

Multimeter

If normal, go on with the next

step.

8 Err4

Alarm

The

temperature

does not go

up during

the heating.

3. Check whether the relevant

wiring harness is broken.

Eyeballing

Multimeter

If normal, change power

drive board.

Summary of Contents for HT1006TXVE

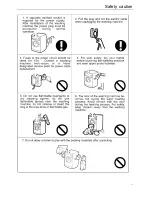

Page 6: ...Safety caution 6 ...

Page 7: ...Safety caution 7 ...

Page 8: ...Safety caution 8 ...

Page 9: ...lnstallation 9 lnstallation 9 ...

Page 10: ...Installation 10 ...

Page 11: ...Functions 11 ...

Page 12: ...Functions 12 ...

Page 13: ...Function schedule 13 ...

Page 14: ...Function schedule 14 Function schedule 14 ...

Page 15: ...Troubleshooting 15 ...

Page 19: ...Wiring circuit 19 ...

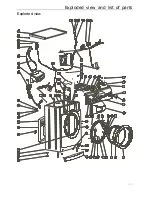

Page 20: ...Exploded view and list of parts 20 Exploded view 78 77 ...