– 39 –

Replacing Sealed System Components

Evacuation and Charging Procedure

The following information covers the evacuation and charging procedure for sealed system work.

WARNING:

Before cutting or using a torch on refrigerant tubes, recover the refrigerant from the system using

approved recovery equipment.

Never charge new refrigerant through the purge valve. This valve is always located on the high

pressure side of the system.

Never apply heat from any source to a container of refrigerant. Such action will cause excessive

pressure in the container.

Always wear appropriate PPE (Personal Protective Equipment) when working with refrigerants and

nitrogen holding a charge in some replacement parts. Contact with these gases may cause injury.

1. Evacuate the system to ~20-in. vacuum using the refrigerator compressor and/or recovery pump.

2. Purge the system using nitrogen at 25-35 SCFH.

3. Perform necessary repairs to the sealed system.

4. Pressurize the system to 250 PSIG with nitrogen and test for leaks.

5.

2QFH FRQ¿UPHG WKDW QR OHDNV DUH SUHVHQW HYDFXDWH WKH QLWURJHQ DQG XVH WKH FRPSUHVVRU WR SXOO

the system back into a vacuum.

6.

&KDUJH WKH V\VWHP ZLWK WKH H[DFW DPRXQW RI UHIULJHUDQW VSHFL¿HG RQ WKH QDPH SODWH RU VSHFL¿HG RQ

the instruction sheet included with the component being replaced.

7. Reinstall caps to Schrader ports.

Summary of Contents for GE ABE21D

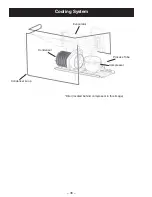

Page 11: ... 11 LUÀRZ ...

Page 33: ... 33 Main Board Connector Locations J10 J8 J11 J13 J4 J3 J1 J2 J7 J9 ...

Page 40: ... 40 Schematic ...