35

35

Outdoor Installation

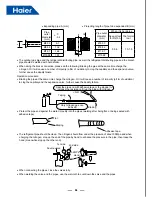

Operation procedure:

B. Leakage test

■

The outdoor unit has been executed the leakage test in the factory. The pipe should be executed leakage test

individually and forbidden to test after connecting with stop valve.

■

Refer to the below figure to charge the nitrogen into the unit to take a test. Never use the chlorin, oxygen,

flammable gas in the leakage test. Apply pressure both on the gas pipe and the liquid pipe.

■

Apply the pressure step by step to the target pressure.

■

a. Apply the pressure to 0.5MPa for more than 5 minutes, confirm if pressure goes down.

■

b. Apply the pressure to 1.5MPa for more than 5 minutes, confirm if pressure goes down.

■

c. Apply the pressure to the target pressure (4.15MPa), record the temp. and the pressure.

■

d. Leave it at 4.15MPa for over 1 day, if pressure does not go down, the test is passed.

■

Meanwhile, when the temp. changes for 1degree, pressure will change 0.01MPa as well.

■

Correct the pressure.

■

e. After confirmation of a~d, if pressure goes down, there is leakage. Check the brazing position, flared

position by laying on the soap. Modify the leakage point and take another leakage test.

■

After leakage test, must execute the evacuation.

C. Evacuation

Evacuate at the check valve of liquid stop valve and both sides of the gas stop valve. The oil equalization pipe

also must be vacuum (executed at the oil equalization pipe check valve respectively).

Nitrogen

To indoor

Gauge manifold

Lo

Hi

Lo handle

Hi handle

Leakage test passed

Evacuation begins

Evacuation ends

Check vacuum

Charge refrigerant

After reaching -100.7KPa

or less (below-755mmHg),

let the vacuum pump

running continuously for

over 1hour.

Leave it for over 1

hour, vacuum pointer

does not arise.

If vacuum pointer arises, it shows there is water or leakage in the

system, please check and modify it, and then evacuate again.