IV.

OPERATING SYSTEMS

57

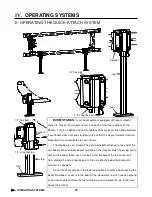

E. OPERATING THE QUICK-ATTACH SYSTEM

DETACHING FROM THE MACHINE

FOLLOW THESE STEPS:

1. Determine where to place the boom once it is off the machine.

2. Lower the boom and secure the boom stands in the down position.

3. With the booms folded, horizontally extend the booms so that the

folded tip is approximately even with the rear of the cab.

4. Disengage the quick attach lock assemblies.

5. Slowly and gently lower the boom and transom assembly until the

quick attach hook is free of lock pin.

6. Make sure the solution valves are OFF and turn off the engine be-

fore disconnecting any hoses or electrical lines.

7. Once you have cleared the lock pin, unhook the hydraulic, solu-

tion, electrical, and foamer lines (if equipped), being careful not to

leave the ends in a place that they may get damaged or contami-

nated.

8. If no other attachment is going to be installed, re-lock the quick

attach lock assembly to keep it safe from damage. Be sure to

unlock it again when installing an attachment.

9. Start the machine and slowly back out and away from the boom.

Alarms will sound notifying you of modules offline, accept the

warnings.

PAGE AND FIGURE REFERENCE

58

59

60; FIGURE 60-1

60; FIGURE 60-2

60; FIGURE 60-3

61; FIGURES 61-1 thru 61-4

FIG. 57-1

OPERATING SYSTEMS

Summary of Contents for UpFront STS 16

Page 119: ...113 IX TROUBLE SHOOTING NOTES TROUBLE SHOOTING...

Page 127: ...NOTES NOTES...