21

OPERATION MANUAL

5.4 BLADE GUIDE ADJUSTMENT

The blade guides are set before the machine leaves the factory but made need to be adjusted

due to movement while shipping, or general wear and tear after long operation.

F

ig

. 5.8

Cap Screws

F

ig

. 5.9

To adjust the support roller

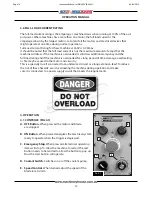

1. DISCONNECT THE BAND-SAW FROM THE POWER SUPPLY

2. Make sure that the blade is oiled and correctly

tensioned.

3. Raise and lock the bow saw for easy access. Slide the

blade guides as close as possible together and lock in

place. Remove the blade guards by loosening the

button head screws. (Fig.5.7)

4. Loosen the cap screws (Fig.5.8) and adjust the blade

guide housing so the back of the blade just touches

the bearing, making sure the guide housing is not

tilted.

5. Tighten the cap screws.

NOTE:

To access the cap screws on the other blade guide

you will need to remove the two Phillips head screws and

move the limit switch and its bracket out of the way.

To adjust the side bearings

1. Loosen the lock nut on the top of eccentric bolt.

2. Using a spanner on the hex section between the

bearing and the casting, adjust the bearing, so it is

against the side of the blade. There should be no

clearance. (Fig. 5.9)

3. Tighten the lock nut making sure that the eccentric

bolt does not turn.

4. Adjust the other ball bearing guide.

5. Repeat steps 1-4 on the other set of ball bearing guides

on the opposite side of the saw bow.

F

ig

. 5.10

Lock Nut

Hex Section

F

ig

. 5.7

Button Screws

Page 21

Instruction Manual for EB-260V (B062V)

04/04/2019