Operation Manual

Total 26

page 22

In case too tight mesh between tool shank and spindle taper and the tool cutter could not fall

down after several strokes, then you have to use the normal way by using a taper wedge to

dismounting the tool cutter.

If milling cutter is used, be sure to take away the screw on the tool holder screwed on the end

of the spindle, the milling cutter then could be easily dismounted.

Warning: The nob (16)must not be pulled out while tool mounting or machine

Running, otherwise, the spindle will goes up quickly which results tool

cutter falls down. It is really dangerous.

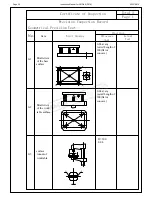

7.3 Changes for the spindle speed and feed rate:

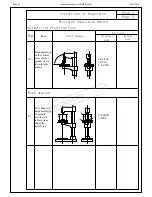

Spindle speed change could be made by moving the two levers ( 14 ) and ( 15 ) located in

the front of the spindle box. Relations between spindle speed revolution and levers position

is indicated at the speed change label. Meanwhile, the digital meter indicates the actual

spindle revolution.

As mounting or dismounting tool cutter or adjustment of work piece needs spindle rotation

by manual, therefore, the lever in the right side position shall be in the “idle” position, so

spindle rotation could be easily obtained.

Changes of the feed rate could be realized by using the lever ( 5 ) in the upper right side

position of the spindle box. As micro manual feed needs disengagement of the auto feed,

therefore, the lever shall also be in the “idle” position.

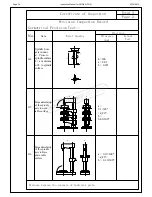

7.4

Selection and operation of the spindle feed:

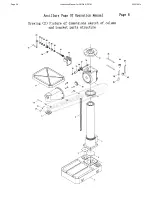

There are three types of spindle feed selections for your choice as per the requirement of

your machining:

Manual feed: Simply moving the feed lever( 4 )at the right side of the spindle box, the

spindle will move down if turned the lever in counter clockwise and the

spindle will move up if turned the lever in clockwise.

Auto feed: There are three levers( 4 ),at the end of each lever equipped with a push

button.Push one of any three buttons( SB4 ), auto feed could be realized as

per your required pre-set feed rate. Push one of any three buttons( SB4 ) once

again, the auto feed will be stopped immediately.

Page 24

Instruction Manual for GHD-50 (D178)

23/12/2014