Operation Manual

Total 26

page 23

Manual micro feed: Spindle micro feed needs two steps. First, put the feed rate lever( 5 )in the

“idle” position. Secondly, push button ( SB4 ), then push up the micro

feed hand wheel( 3 ) and make sure that the clutch is engaged, now the

micro feed hand wheel could be turned and micro feed of the spindle

works.

7.5

Cutting depth control:

For the batch production, you need control cutting depth. A scale in front of spindle box could

meet your requirements. Loosening knurled screw ( 20 ) by turning nob ( 2 ), moving the scale

to the required depth, then fastening the knurled screw( 20 ). Now the machining depth could

be controlled.

7.6

Application of the digital scale:

A small round battery is fixed on the right side position of the spindle box for digital

readout. With this scale, moving distance of the spindle could be easily readout. Except the

battery switch, a “reset” push button and an “English or Metric” converter push button are

available. Cutting depth could be readout at any time and cutting depth could also be set in

advance. This function will be helpful for small batch or single work piece machining.

7.7

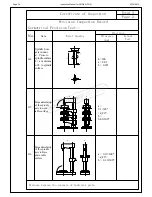

Tapping:

Put the “Selection Switch”(18 ) on the tapping position first, turn the feed lever( 4 ) and let

the tap approaches the work piece, a proper manpower force (based on the size of screw)

shall be exerted in order to let the tap comes into the hole. The spindle will be rotated in

reverse when the screw depth is reached, and the tap comes out.

Suppose, tapping job needs stop, push button ( SB4 ) of the hand lever( 4 ) then spindle will

have reverse revolution. and tap returns back.

7.8

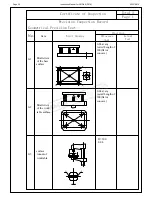

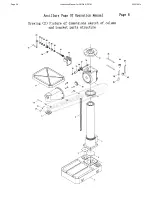

Milling

Choosing milling cutters and accessories as per the machining requirements and shape of the

work piece. Milling cutters could be fixed on the spindle via tool holder or drill check. Put

accessories on the worktable and fasten it, turn the worktable and let its pin in the bottom

approaches right side position of round column and let lock block clamps the pin and fastens

it by screw, be sure to clamp it in force by clamping levers( 6 ) and ( 22 ) .

Page 25

Instruction Manual for GHD-50 (D178)

23/12/2014