Operation Manual

Total 26

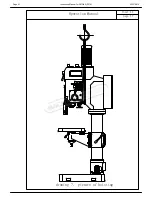

drawing(1)picture of appearance of machine

Page 5

column

base

bracket seat

worktable

spindle box

electric box

speed-change box

1

2

4

3

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

21

22

23

1"

20

10

0"

0

mm/in

OFF

ON/O

6.25

0.2

150

130

140

120

100

110

90

70

60

50

40

30

80

2"

3"

150

86

6"

5"

4"

mild steel

cast iron

6.94 6.21

0.3 0.2

10.42

8.33 9.25 9.38 10.40

11.57

0.2 0.3 0.2 0.3

8.09

0.3

30

35

40

45

50

240

230

220

190

200

170

180

210

160

/min

n

400

695

515

215

300

8"

7"

F

KN

1.67 3.33 2.67

1.20

5.21

3.34

4.17

mm/

s

0.2 0.2 0.2 0.2 0.3 0.2

0.1 0.2 0.2

mm

D

10

20

15

25

5.78

0.3

The cutting rating chart

for reference

9"

330

1050

95

TOOL SETTING

TOOL DISMOUNTING

790 250 0

580 180

72

52

x

min

OFF

13

0.30

0.40

0.20

0.10 0

mm/r

4

3

2

1

Chart of lubrication position

lubrication period

Oiling once for each shift

Oiling once for each shift

Changing grease once every 6 month

Oiling once for each shift

Oiling once for each shift

Oiling once for each shift

6

5

6

4

Worm bearing for Carriage lifting

Surface of upright column

Carriage lifting device

No.of lubrication position

5

3

2

1

Oil pool of spindleboox

Surface of main spindle sleeve

Surface of upright column

lubrication position

No.40 lubricant

Grease designation

Page 7

Instruction Manual for GHD-50 (D178)

23/12/2014