5.52.693.00.01.00

13

12.3.1

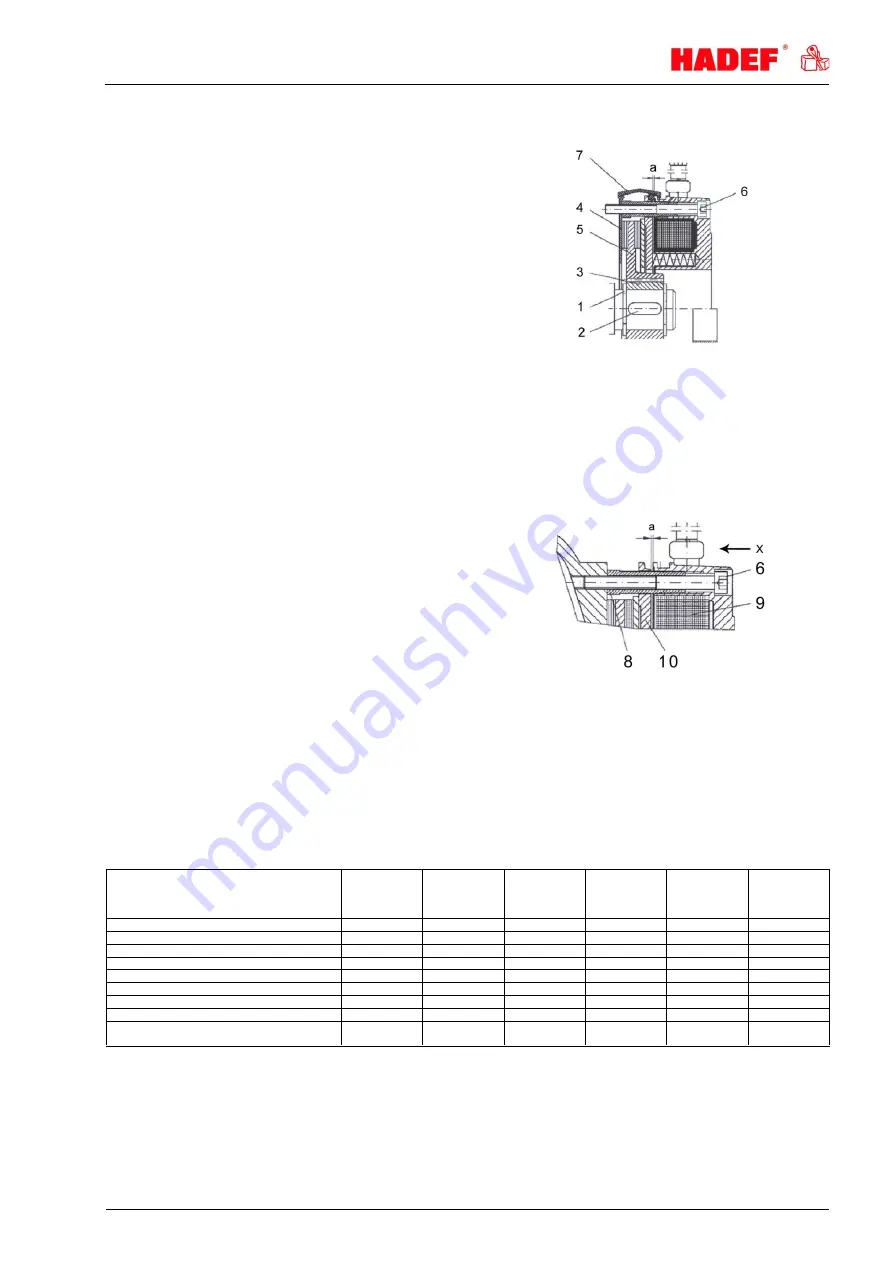

Assembling the brake

1 Insert the retaining ring (1) into the shaft slot.

2 Insert the feather key (2) into the motor shaft.

3 Fix hub (3) with retaining ring (1).

4 Assemble the friction plate (4) if existent.

5 Push the rotor (5) onto the hub (3).

6 Lock the magnet body with the 3 fastening

screws (6).

7

Set air gap “a” (refer to “adjusting the air gap”)

8 Assemble the dust-protection ring (7) if

existent.

9Electric connection

Illustration 9

12.3.2

Disassembly of the brake

Disassembly is performed in reverse order to the assembly.

12.3.3

Adjusting the air gap

View "X" on the brake.

1 Loosen the locking screws (6) by half a turn.

2 Turn the cap screws (8) into the magnetic body

(9) anti-clockwise.

3 By turning the locking screws (6) clockwise,

move the magnetic body (9) towards the

anchor plate (10) using a feeler gauge until

nominal air gap “a” is reached (see table).

4 Unscrew the cap screws (8) from the magnetic

body clockwise.

5 Tighten the locking screws (6).

6 Check the air gap again and re-adjust if

necessary.

Illustration 10

13

Inspection

13.1

Periodic checks

Independently from the regulations of the individual countries, lifting devices must be checked at least yearly

by a qualified person or licensed qualified person regarding its functional safety.

at

commissioning

daily

checks

1st maintenance

after

3 months

Inspection

Maintenance

every

3 months

Inspection

Maintenance

every

12 months

check screw connections

X

X

check the bearings

X

check the trolley wheels

X

check lubrication of the driving pinion

X

X

buffers - check correct position and wear

X

X

electric motor* - check the brake lining

X

electric motor* - check the brake

X

X

pneumatic motor*

X

X

X

Have the equipment checked by an expert

(periodic inspection)

X

*as far as applicable

14

Service

14.1

Electric motor

For the motor it is sufficient to keep the cooling airways clean and monitor the roller bearing and its

lubrication status.

A high temperature fat must be used if the roller bearing is replaced.