7

5.3.

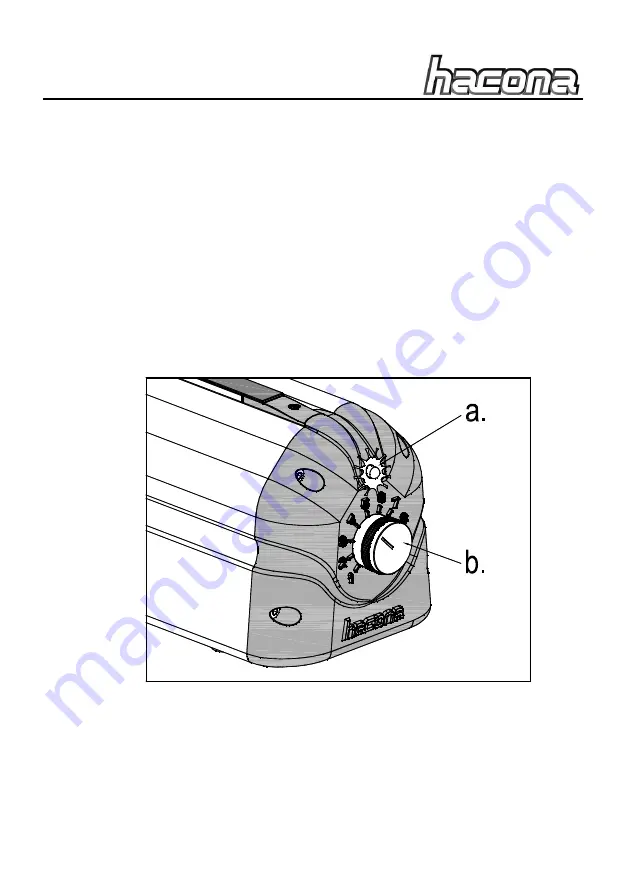

Setup

The machine is ready for operation after it is connected to the electricity

network. The yellow light of the LED (lamp) indicates the ready state.

(Figure 4 “a”)

.

The correct sealing time should be set referring to the type and width

of the used film. For effecting a trial sealing set the sealing time regulatory

button

(Figure 4 “b”)

to the lowest setting (1). Place the film between the

sealing head and the sealing electrode. Close the sealing head and wait

for the end of the sealing time while continuously pushing it down. During

sealing the light of the LED (lamp)

(Figure 4 “a”)

changes from yellow to

red. In order to achieve a perfect seal it is advisable to keep the handle

down for a few seconds after the sealing ends so that the seal cools down

under pressure and becomes extremely solid. After the cool down time lift

the handle and the seal is ready.

Figure 4 Operation setting

If the sealing of the film is not perfect or the bag is not sealed properly,

the sealing time has to be increased by changing the sealing time

regulatory button

(Figure 4 “b”)

to a higher setting.

The trial sealing always has to be carried out at a low setting and if

necessary the value needs to be increased by small steps. Sealing carried