3-10

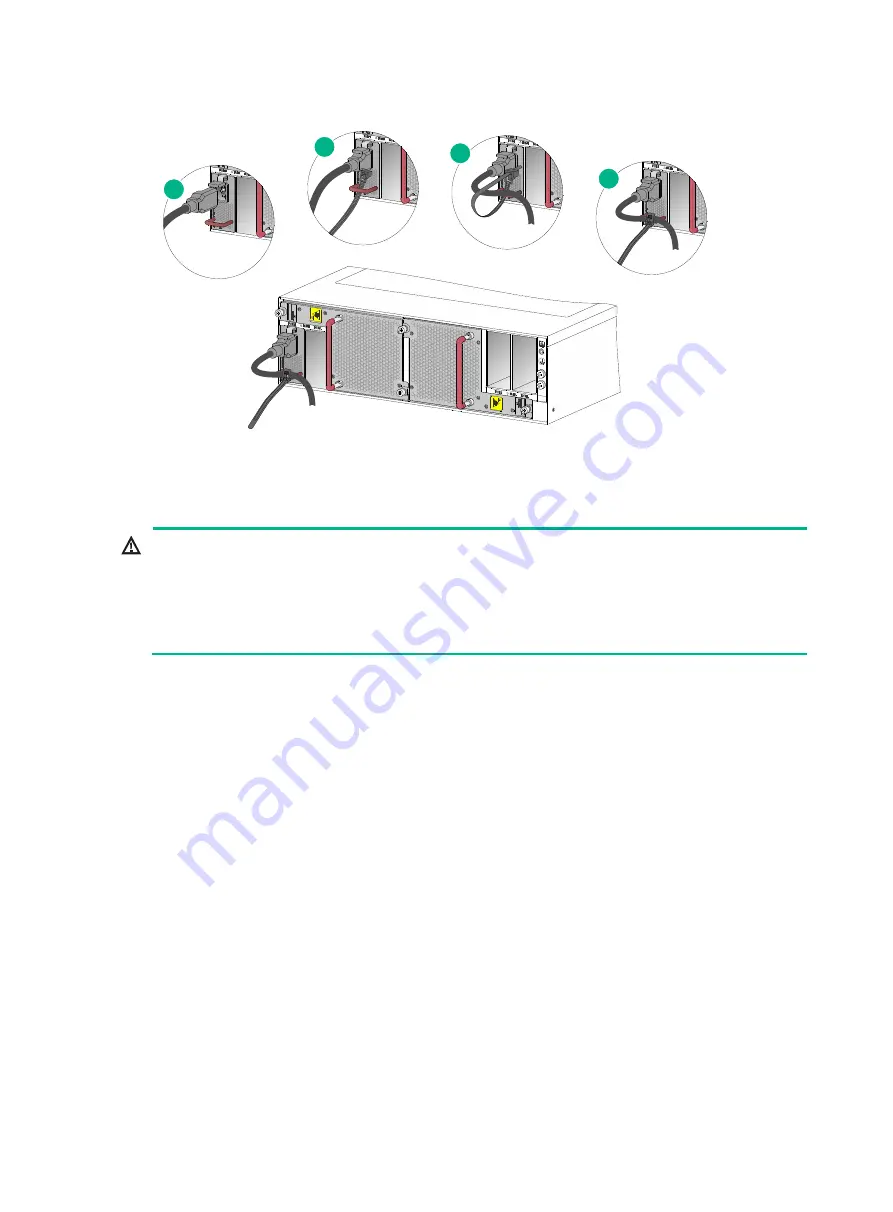

Figure 3-12 Using a removable cable tie to secure the power cord to the device

Connecting the DC power cord

WARNING!

•

Before connecting the DC power cord, make sure the circuit breakers for both the positive lead

(

+

) and the negative lead (

–

) are turned off.

•

To avoid electrical shock, a plastic cover is installed over the terminal blocks. Remove the cover

when you connect the DC power cord and install the cover in time after you connect the DC

power cord.

To connect the DC power cord:

1.

Remove the plastic cover over the wiring terminals, and use a Phillips screwdriver to remove

the M5 screws.

The recommended torque is 20 kgf-cm (1.96 Nm).

2.

Connect the wire marked with the negative polarity symbol (

–

) to the negative terminal (–) on

the power supply. Connect the wire marked with the positive polarity symbol (

+

) to the positive

terminal (

+

) on the power supply.

3.

Fasten the M5 screws to secure the wires and then install the plastic cover.

4.

Connect the other end of the power cord to a DC power source.

5.

Examine the input status LED (IN OK) on the power supply. If the LED is green, the power

cord is successfully connected. If the LED is off, examine the installation, troubleshoot the

problems, and try again until the LED is on.

1

2

3

4