3

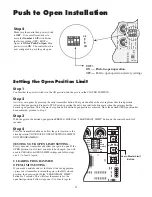

Gate in the Closed Position

Pinch Area (gray)

Gate in the Open Position

Pinch Area (gray)

Two inch minimum

Two inch minimum

Determining The Mounting Position

of The Post Bracket Assembly

Step 1

With the gates

closed

, adjust the post bracket assembly and the gate

bracket until the operator is level. While holding the operator level,

use C-clamps to temporarily keep the post bracket assembly and

gate bracket in their respective positions on the fence post and gate.

Push to Open Installation

Swinging gates shall not open into public access areas!

A "Push-to-Open" gate opens

out

from the property.

A Push-to-Open Bracket is required for this type of installation

(

see

Accessory Catalog

). If you have a pull-to-open gate (gate opens

into

the

property), return to page 3; step 3.

In a PUSH-TO-OPEN installation the operators are installed while the gates

are in the

closed

position.

3/8" x 2" Bolt

3/8" Nut

Post Pivot Bracket

Post Bracket

Post Bracket

3/8" Lock Washer

Post Bracket Assembly

3/8" Washer

Step 2

After verifying that you have the best position

for the post pivot bracket, insert the

5

/

6

" x

3

/

4

"

bolt through the aligned holes of the post bracket

and post pivot bracket and fasten it with the

5

/

6"

washer and nut.

IMPORTANT:

If you loosened the clamp on

the post bracket to achieve the optimum position,

tighten it in its new position and recheck the gate

bracket with the gate in the open position (move the

gate bracket and re-clamp it if necessary).

IMPORTANT:

While determining the mounting point for the post

pivot bracket assembly be sure that the position allows for maximum

clearance between the gate and the operator in both the open and closed

positions, as shown in the diagrams below. This clearance will give the

operator the most efficient leverage point for opening and closing the

gate and more importantly provides the least possible pinch area.